Your hunt for a plastic injection molding manufacturer begins the minute you design a new product that might require the procedure. It can also happen if your company is keeping up with times and redesign their line of products to keep being competitive in the market. Manufacturing methods evolve, and sometimes we find out the hard way because we get too comfortable with our ways until this course of action hits our profits. The hard facts are that there is a large number of questions that might pop in the way as we embrace this industry or if we are adapting to their methods for being out of the loop for too long.

These are some of the most common inquiries you will face in the way with the best answers we can provide:

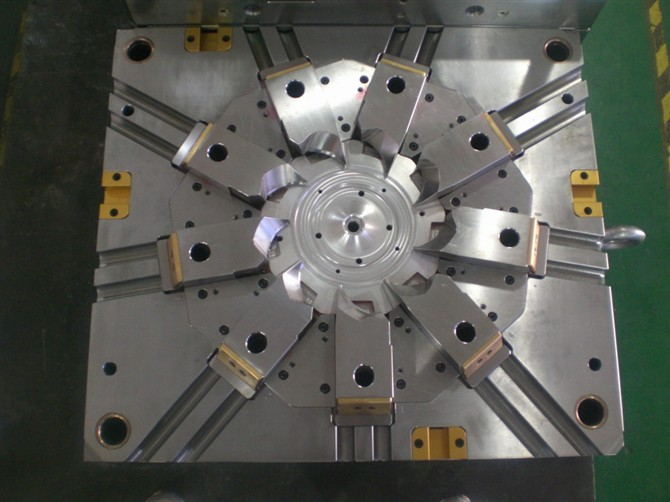

plastic injection molding, *picture from ruitai-precision.com

It is best to work with a manufacturer that has In-house mold tooling?

Working with a plastic injection molding manufacturer that has an in-house team to manage your project since the moment is conceived is one of the best courses of actions for any developer, but it relies heavily on the type of budget you are managing. When it comes to logistics, all the details can be worked out in real time with designers and technicians, so the delivery of the finished product is shortened. Take into account that if the company has the means to provide a prototype you have an actual chance of saving a lot of money if your product doesn’t need a large number of revisions.

How Many Molding Machines should have an efficient manufacturer?

This is a subjective topic since most plastic injection molding manufacturers work to the best of their capacities with the hardware they have. It’s unreal to think that all their machines will be used on a single project unless they are in the process of undertaking a big order by a large corporation. Even in such a scenario, these companies administer their resources as best as they can to deliver their orders in time. A more accurate inquiry should be to ask about the capacity of their machines to handle heavy tasks or their hardware’s ability to work with large molds, but most of these services handle small business by the volume these days.

What is the longstanding guarantee of a mold for a project?

Similar to the previous topic this question also hinges on a large number of factors that can affect the performance of the mold depending on the type of project that is being developed. A client probably needs a sturdy mold for an extensive run of products, but the budget doesn’t allow for it. While it’s not the job of the plastic injection molding service to make calls on business decisions on the client’s end, the best course of action would be to recommend a cheaper mold in the case of a new product. If the product has a stable position already, a sturdier mold with a lower production run to secure profits that can be used to restock.