Rapid Tooling and Its Relation to Small Production

Rapid tooling is part of the crucial technological transformation that is

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

ISO 9001:2015 | IATF 16949

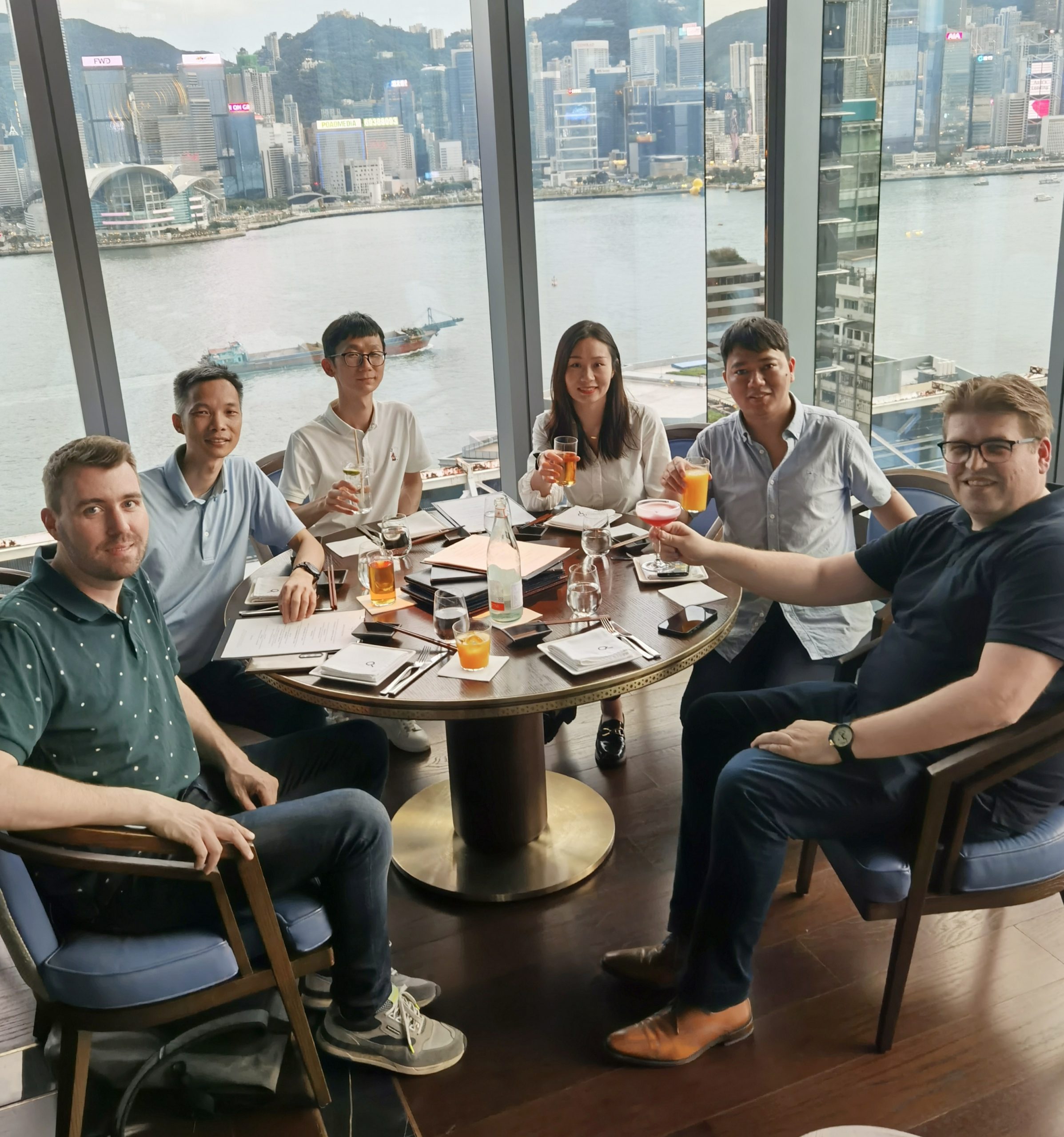

Founded in 2017, APT-Mold has quickly become one of the leading rapid prototyping companies in China, serving clients across diverse industries and countries. We have earned a strong reputation for delivering professional, reliable, and precise services in rapid prototyping. With ISO 9001 and IATF 16949 certifications, we ensure the highest standards in manufacturing and quality assurance.

Specializing in a broad spectrum of advanced manufacturing solutions, APT-Mold provides cutting-edge technology such as CNC machining, plastic injection molding, sheet metal fabrication, vacuum casting, compression molding, and pressure die casting.

Our rapid prototyping services are designed to meet the unique requirements of industries such as automotive, medical devices, home appliances, consumer goods, and commercial products.

At APT-Mold, we prioritize your unique needs, offering tailored solutions that align with your business goals. Our engineering team supports you at every step, from initial product development through to mass production.

Trusted by clients in more than 20 countries, we focus on optimizing designs, reducing costs, and integrating advanced automation to deliver faster turnaround and reliable results for every project.

APT-Mold provides end-to-end rapid prototype services, spanning product development, mold design, CNC prototyping, injection molding, and assembly.

With a team of 100 seasoned experts, we bring extensive experience in rapid modeling across diverse industries. Our proven expertise ensures high-quality results and the capability to handle projects of any scale or complexity.

With over 4,000 projects delivered on schedule worldwide, we have earned the trust and support of our customers. We are committed to consistent product quality and on-time delivery.

We strictly follow the ISO quality system and are ISO 9001:2015 certified. With advanced inspection and testing equipment, we ensure that all materials and parts fully meet your design and performance requirements.

Simply upload your CAD files and project details, and we will provide a clear lead time and highly competitive quotation within 24 hours. As one of the trusted providers of rapid prototyping services in China, we offer full flexibility with no minimum order requirement, helping you bring ideas to market faster.

With advanced production equipment and over 1,600㎡ of modern manufacturing facilities, we can efficiently handle both small-batch custom orders and large-scale mass production. Our professional prototype molding services ensure smooth transitions from prototype to final production.

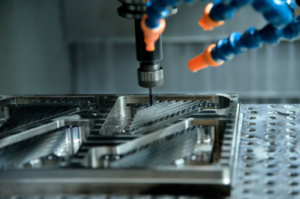

CNC machining is a subtractive manufacturing process that uses 3-axis, 4-axis and 5-axis milling, turning, or turn-mill compound processes to cut solid plastic and metal blocks into final parts.

APT’s CNC machining services are structured for speed, flexibility, and excellent quality no matter the volume of parts.

Polyurethane vacuum casting is often used as a substitute for plastic injection molding because it is ideal for small volume, the molds create up to 20 high-fidelity copies from the original master pattern.

We offer a complete solution for creating master patterns and cast copies based on your CAD designs along with a full line of finishing services such as painting, pad printing and more.

Injection molding is a manufacturing process that consists of filling a metal mold cavity with liquid plastic resin, which then cools and forms a plastic part.

Our manufacturing experts are committed to providing you with the highest level of professional support for injection molding, and carry out a comprehensive design for manufacturing (DFM) review for every tool. You’ll receive superior results while saving time and money.

Sheet metal is a comprehensive cold working process for metal sheets, including shearing, punching-cutting compounding, folding, riveting, splicing, forming, etc.

The efficiency and high precision of sheet metal fabrication, coupled with APT’s variety of materials, and post-processing options means you can get parts for automotive, energy, industrial, medical, consumer products, etc. hitting your goals just right.

3D printing or additive manufacturing is a process of making three dimensional objects from a digital file.

We are your one-stop shop for accurate, precise, custom 3D-printed parts at a competitive price. 3D printing works best for functional prototypes, complex designs, and as well as end-use applications.

A variety of treatments adopted to improve your parts appearance, performance and durability including sanding, polishing, anodizing, painting, plating, pad & silkscreen printing and many more.

Whether in metal or plastic, from a one-off prototype to mass production, we have everything you need to take your project that final step to perfection.

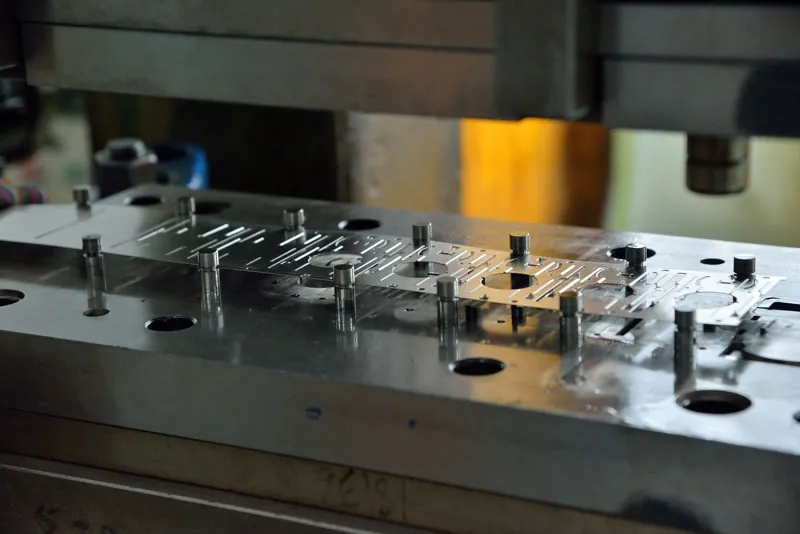

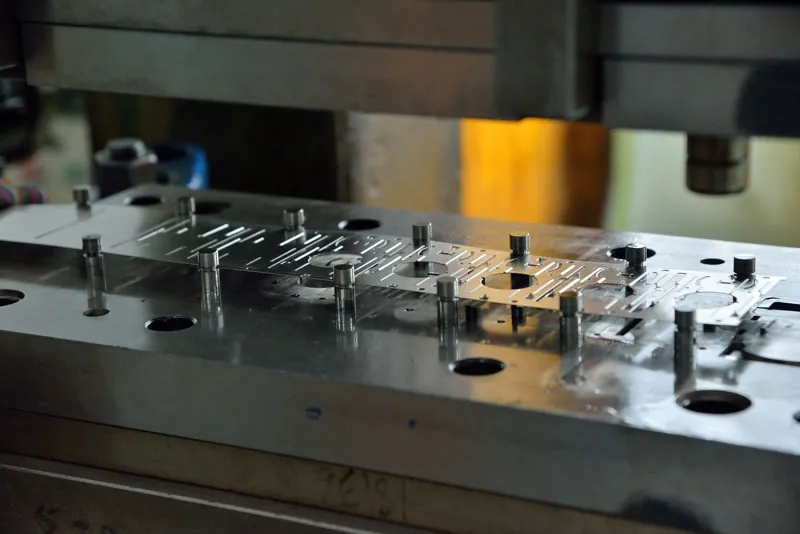

CNC machining is a subtractive manufacturing process that uses 3-axis, 4-axis and 5-axis milling, turning, or turn-mill compound processes to cut solid plastic and metal blocks into final parts.

APT’s CNC machining services are structured for speed, flexibility, and excellent quality no matter the volume of parts.

Polyurethane vacuum casting is often used as a substitute for plastic injection molding because it is ideal for small volume, the molds create up to 20 high-fidelity copies from the original master pattern.

We offer a complete solution for creating master patterns and cast copies based on your CAD designs along with a full line of finishing services such as painting, pad printing and more.

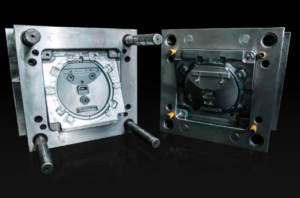

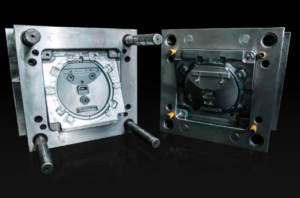

Plastic injection tooling makes precision-engineered molds used to shape molten plastic into desired components. These tools are essential for manufacturing a wide range of plastic parts with accuracy and consistency.

APT offers a wide variety of tooling solutions tailored to your project requirements, including cold/hot runner, single/multi-cavity, family molds, 2K mold, etc. aiming to support your prototype, low, middle or large volume of manufacturing with superior quality in a cost effective way.

Sheet metal is a comprehensive cold working process for metal sheets, including shearing, punching-cutting compounding, folding, riveting, splicing, forming, etc.

The efficiency and high precision of sheet metal fabrication, coupled with APT’s variety of materials, and post-processing options means you can get parts for automotive, energy, industrial, medical, consumer products, etc. hitting your goals just right.

3D printing or additive manufacturing is a process of making three dimensional objects from a digital file.

We are your one-stop shop for accurate, precise, custom 3D-printed parts at a competitive price. 3D printing works best for functional prototypes, complex designs, and as well as end-use applications.

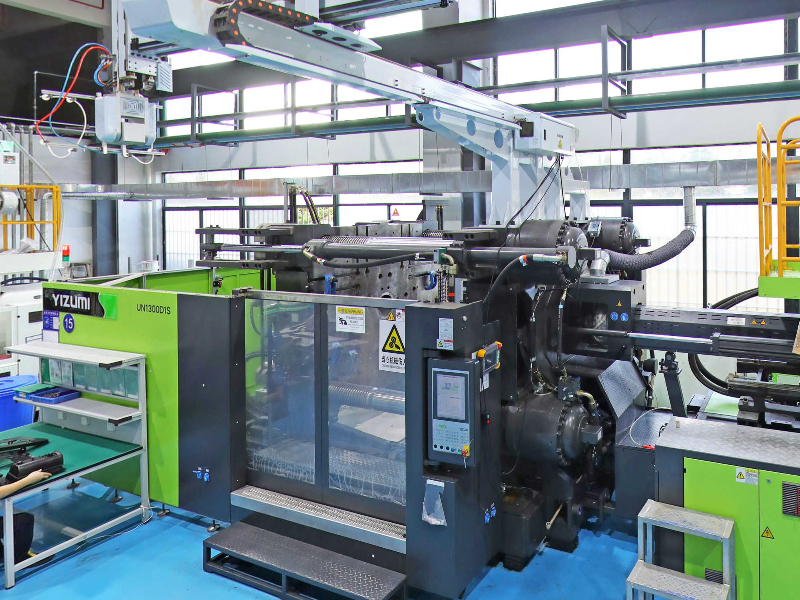

Injection molding is a manufacturing process that consists of filling a metal mold cavity with liquid plastic resin, which then cools and forms a plastic part.

Our manufacturing experts are committed to providing you with the highest level of professional support for injection molding. APT adopts automated operations to magnifies the efficiency, consistency, bringing higher production rates. You’ll receive superior results while saving time and money.

APT-Mold’s rapid prototyping services are widely used in different industries, ensuring high-quality results through advanced manufacturing techniques.

Automotive

APT-Mold’s rapid prototype service, backed by IATF 16949:2016certification and extensive experience, is trusted by world-class automakers like Tesla and Ford for prototyping and manufacturing high-quality automotive parts.

Medical and Healthcare

APT-Mold collaborates with leading medical device manufacturers, wearable tech innovators, suppliers, and research labs to provide top-tier rapid prototyping services while continuously scaling manufacturing capacity.

Consumer Products

With a full suite of manufacturing services available, APT-Mold is your ideal source for all your component fabrication needs.

Simply click on the Request A Quote button and follow the instructions.

Receive a project quotation within 24 hours.

Confirm the order & start the manufacturing process.

The order was completed and shipped worldwide to your location.

Rapid tooling is part of the crucial technological transformation that is

Control Numerical Control Machining (or CNC Machining) has seen a huge

There are more than 85,000 of materials available for plastic injection

In the world of precision manufacturing, the difference between a

Plastic injection molding allows automobile manufacturers to make multidimensional components on

Finishing is what gives a CNC-machined part its final look

When you hold a flawlessly machined part in your hand,

Global healthcare growth means that every implant, pump, and wearable

Precision matters since even a micrometer of error in a