- Building AB, No. 7 Shiji 2nd Road, Torch Development Zone, Zhongshan City, Guangdong Province, 528437, China.

- enquiry@apt-mold.com

- +86 18814246095

With extensive experience in prototyping and manufacturing automotive parts, we specialize in advanced manufacturing processes such as CNC machining, 3D printing, and injection molding. Utilizing a wide range of raw materials, including aluminum, steel, and high-performance plastics, we efficiently produce precise and durable finished parts and assemblies that meet industry standards.

+86 18814246095

APT continuously scales its offerings, delivering an ever-expanding menu of manufacturing capabilities

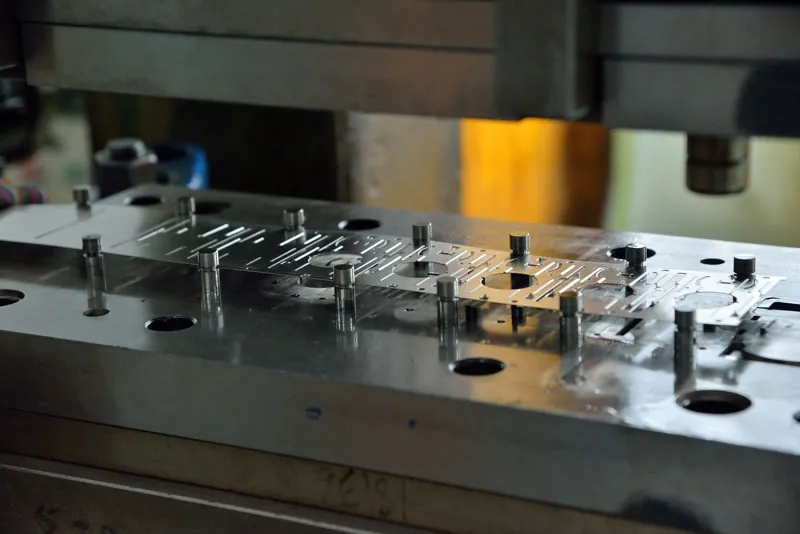

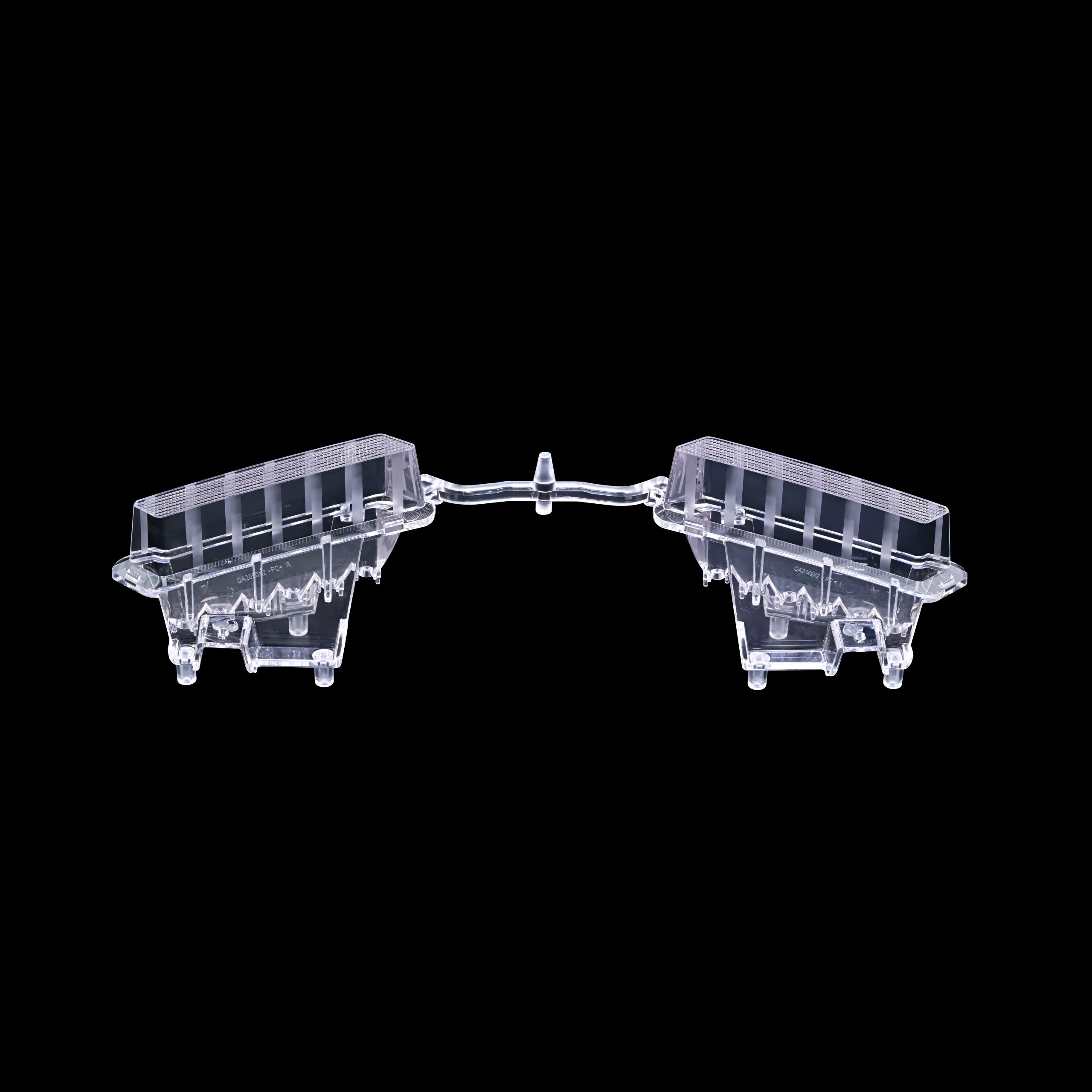

Injection Molding

Injection molding ensures high-quality car part prototypeswith exceptional efficiency and cost-effectiveness. This process optimizes production timelines without compromising precision or durability, making it ideal for businesses aiming to scale production while maintaining product excellence.

CNC Machining

CNC machining leverages advanced technology to accelerate manufacturing cycles for the automotive industry, lower development costs, and meet the growing demand for product customization. This process ensures precise, high-quality results, making it an essential solution for auto industries requiring efficiency and adaptability in production.

Vacuum Casting

Vacuum casting is a versatile solution for auto parts prototype production,from showroom-quality display models to end-use products. This process not only delivers exceptional detail and surface finish but also accelerates product development and speeds up market introduction, making it ideal for low-volume prototype automobile manufacturing.

Sheet Metal

In auto parts prototyping, sheet metal fabrication is widely used for its durability and adaptability. It allows manufacturers to produce precise, high-quality components, from structural elements to intricate designs, that are essential for automotive applications. Its versatility not only ensures compliance with industry standards but also fosters innovation in vehicle development.

Material selection in the automotive industry to make vehicles lighter, safer and more fuel-efficient at competitive cost.

Polypropylene (PP) is a flexible, fatigue-resistant family of thermoplastics commonly used in automotive interiors, bumpers and other products requiring toughness and light weight. The different grades of polypropylenes are grouped as homopolymers, impact copolymers, offering superior strength-to-weight ratios, and good impact resistance even at cold temperatures. PP also has excellent chemical and heat resistance.

Acrylonitrile Butadiene Styrene (ABS) is another thermoplastic with exceptional impact resistance and toughness. It is a lightweight alternative to metal in dashboard trim, electronics enclosures, hubcap covers and other such automotive applications. ABS is also well-suited to heavy-duty applications, so it can be used for automotive body parts, too. Plastic used in cars, like ABS, helps the body absorb and redistribute energy during an impact, keeping passengers safe.

Polycarbonate (PC) is very thermoformable, and is frequently shaped into see-through headlight lenses where glass is unsuitable due to weight or breakage concerns. Polycarbonate is so resistant to impact that it is often used for car bumpers. This kind of car plastic is highly resistant to weathering, able to handle conditions from rain and snow to heat and cold. Polycarbonate is also lightweight, so it reduces a car’s overall weight, which in turn improves vehicle’s fuel efficiency.

Polyamide (Nylon) is also frequently filled with mineral or glass fibers to improve stiffness-to-weight ratios and improve mechanical properties. This makes it one of the strongest plastics available at APT and—because nylon is self-lubricating, thermally stable and very wear-resistant—is an excellent candidate for engine covers, door handles, gears and fuel caps.

Polyoxymethylene (POM) is renowned for retaining its shape, withstanding exposure to chemicals, and resisting damage from ultraviolet light. Due to these properties, POM is commonly used to construct automotive components that demand high tolerances and durability when exposed to fuels, harsh chemicals, and low temperatures. Applications include interior and exterior trim pieces as well as fuel system components.

Polybutylene Terephthalate (PBT) has excellent chemical and electrical resistance. It is a hard, tough material that absorbs little water. PBT can withstand dynamic stresses and maintains dimensional stability even in extreme heat. It is easy to process due to its fast crystallization and cooling properties. Some common application of PBT includes bumpers, door handles, and other trim components.

Thermoplastic Polyurethane (TPU) can take on both soft and hard forms, is exceptionally resistant to solvents, radiation, and environmental wear. Because of these qualities, polyurethane is well-suited for numerous applications, including tires, bumpers, headrests, car seats, and more.

Stainless Steel is widely used in car exhaust systems and for auto parts such as hose clamps and seatbelt springs due to its flexibility and durability. Its strength, high fatigue and corrosion-resistant properties make it a common choice in chassis, suspension, body, fuel tank and catalytic converter applications.

Aluminum is lightweight material which enhances performance and improve fuel economy. Furthermore, this metal is versatile, strong, efficient, safe, recyclable, and abundant. Some common applications of aluminum include spokes, structural components, gauges, rotors, wheels, rotors, and much more.

Click the “Request a Quote” button and follow the simple steps to begin your auto parts prototype project.

Receive a project quotation within 24 hours.

Confirm your order to initiate the manufacturing of your auto parts prototype.

Deliver your completed car part prototype worldwide to your specified location.

Upload CAD files and submit the important details about your project.

Get quote with DFM analysis within 1 day.

Confirm Quote and Manufacturing Begins.

Qualified parts are delivered straight to your doorstep.

Here are the answers to the frequently asked questions. Any other questions, please feel free to contact us at enquiry@apt-mold.com.

Rapid prototyping plays a crucial role in accelerating development, enhancing design quality, and reducing time-to-market. It is also essential for performance and safety testing, ensuring that vehicles meet industry standards and perform reliably in real-world conditions. At APT-Mold, we leverage this process to create accurate automotive parts and vehicle prototypes, helping manufacturers bring innovative designs to market faster.

Auto parts prototypes are created for testing and design validation, typically made in small quantities using rapid prototyping methods like CNC machining or 3D printing. These prototypes help refine designs before mass production. In contrast, production parts are manufactured on a large scale for final use in vehicles.

Yes, we have 7 years of experience in Auto Parts Prototype services, supported by a team of over 100 experts, making us a trusted name among Automotive Prototyping companies. Our customers include Ford, Tesla, Yanfeng, and so on.

Our automotive prototyping service strictly follows ISO 9001 and IATF 16949 certifications, aligning with global OEM requirements like Tesla and Ford. From prototype automobile design to final production, every part undergoes 100% dimensional checks and destructive testing to meet aerospace-grade precision.

We specialize in auto prototype development, providing high-precision car part prototypes and prototype vehicles for the automotive industry. Our services include rapid prototyping, functional testing, and low-volume production, helping you accelerate product development and market entry.

Absolutely. We comply with REACH regulations and use recycled PETG materials for injection molding. Our energy-efficient CNC machines reduce CO2 emissions by 25%, achieving the eco-conscious auto prototype company’s goals.