- Building AB, No. 7 Shiji 2nd Road, Torch Development Zone, Zhongshan City, Guangdong Province, 528437, China.

- enquiry@apt-mold.com

- +86 18814246095

Rapid tooling technology allows for frequent design changes and rapid iteration. Companies can quickly adjust their designs based on market feedback, making multiple iterations and optimizations to better meet customer needs.

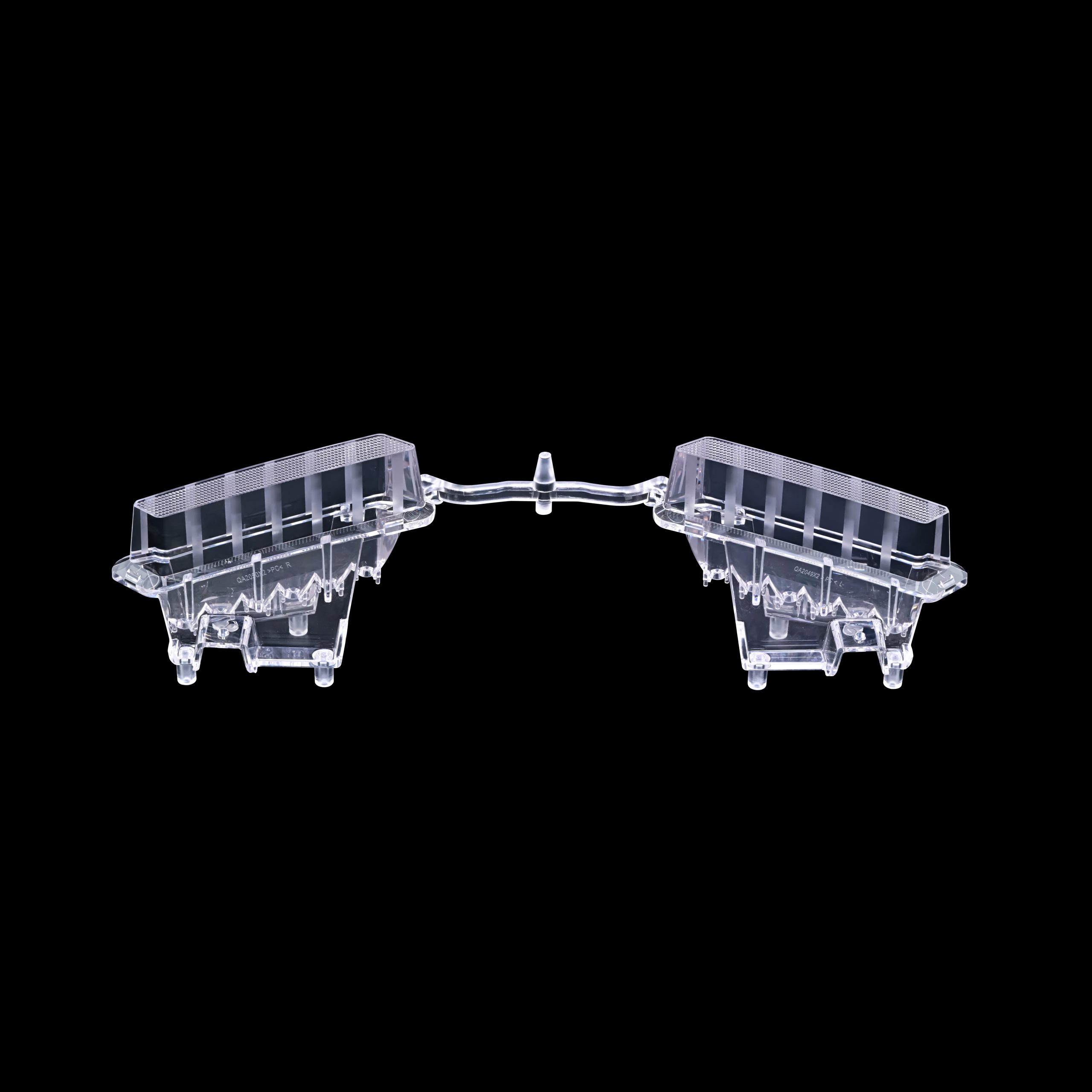

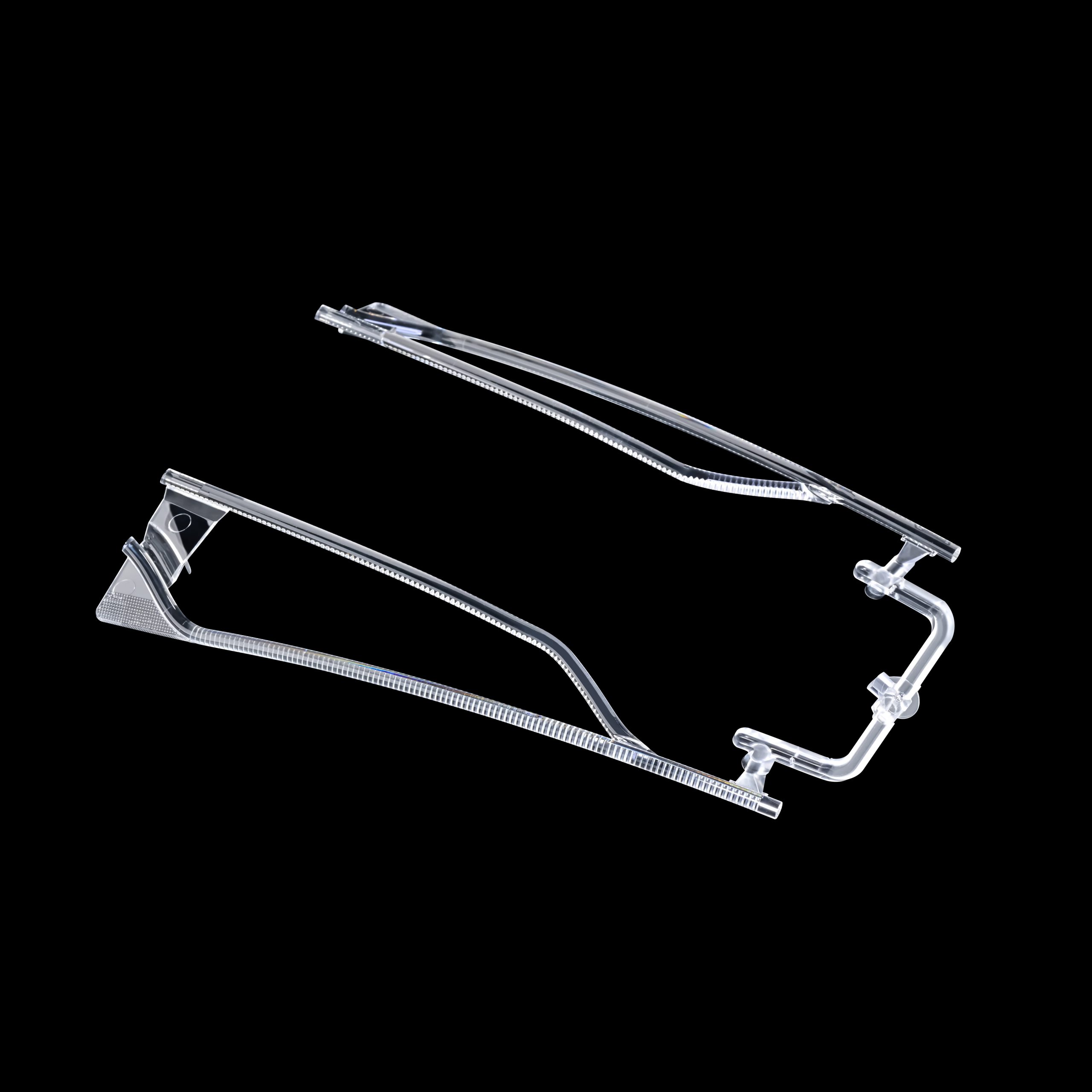

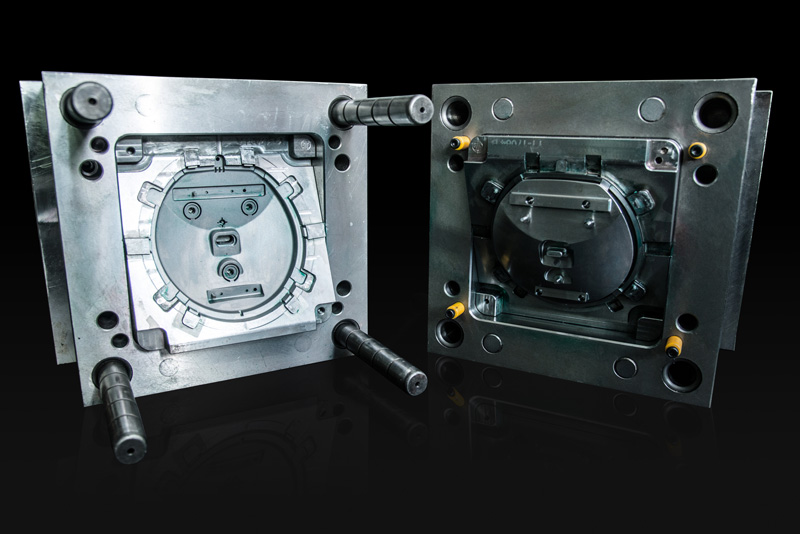

Rapid prototype tooling is a method and technology used to speed up the mold manufacturing process. By combining the traditional mold manufacturing process and rapid prototyping technology, this approach achieves production speeds up to 1.5 times faster than conventional tooling methods.

Rapid Tooling Service | Conventional Tooling Service | |

| Cost | The cost of rapid tooling service is low, and suitable for small batch production and prototype development. | The initial investment is high, but the unit product cost is low, suitable for mass production. |

| Manufacturing period | The development cycle can be shorten to 5-10 days, it can be quickly put into production. | The development cycle is long, and more time is needed for design, processing and debugging. Usually need weeks to months. |

| Materials | Material of Rapid tool is usually P20. It is strength and the price is not much different from aluminum. | Material selection is mainly for high-strength metals, suitable for long-term use and high-load production. |

| Quality and accuracy | Rapid prototype tooling typically offers slightly lower quality and accuracy compared to production tools. However,its service is still sufficient for many prototyping and small-batch needs. | High quality and precision, can meet the strict quality control and precision requirements. |

Rapid Tooling technology is playing an increasingly important role in modern manufacturing, providing efficient, flexible and economical solutions for product development, trial production, verification and small batch production.

+86 18814246095

Rapid tool technology with its short development cycle, low cost, strong flexibility, environmental protection, energy saving and other advantages, plays an increasingly important role in modern manufacturing.

The development cycle time of Rapid tool can be shorten to 5-10 days, which can be quickly put into production.

Manufacturing costs of Rapid tool are relatively low. Customers can validate designs and functionality without investing a lot of money, reducing the high cost of design changes or errors.

Rapid tooling technology allows for frequent design changes and rapid iteration, which can quickly adjust their designs based on market feedback.

Rapid Tooling is suitable for small quantity products customization. For those products with short life cycles or small demand, rapid tooling can provide efficient solutions.

In the case of uncertain market demand, rapid tool technology can help enterprises quickly produce samples for testing and reduce the risk of inventory overstocking.

Through rapid tool manufacturing products can be directly used on the production line, reducing the trial and modification time in the traditional mold manufacturing process.

Rapid tool technology with its short development cycle, low cost, strong flexibility, environmental protection, energy saving and other advantages, plays an increasingly important role in modern manufacturing.

The development cycle time of rapid tooling can be shortened to 5-10 days, which can be quickly put into production.

Manufacturing costs of rapid tooling-making services are relatively low. Customers can validate designs and functionality without investing a lot of money, reducing the high cost of design changes or errors.

Rapid tooling technology allows for frequent design changes and rapid iteration, which can quickly adjust their designs based on market feedback.

Rapid tooling service is suitable for small-quantity product customization. For those products with short life cycles or small demands, rapid tooling can provide efficient solutions.

When market demand is uncertain, rapid tooling service lets companies quickly produce test samples, lowering the risk of ending up with excess inventory.

With rapid prototype tooling, products can be directly used on the production line, cutting out the trial-and-error stage of conventional tooling production.

By quickly responding to market demand and shortening product development cycle, rapid mold technology enables companies to adapt to market changes more quickly and launch innovative products.

+86 18814246095

Here are the answers to the frequently asked questions. Any other questions, please feel free to contact us at enquiry@apt-mold.com.

Rapid tooling is a fast and cost-efficient method to produce prototypes and low-volume products for functional testing. By reducing development time, rapid tooling service helps businesses bring better products to market faster and start generating returns on investment quickly.

APT-Mold's rapid tooling service often uses P20 as its material. It is robust and not very different in price from aluminum.

To achieve rapid results, rapid tooling comes with limitations. For example, rapid tooling has shorter lifespans, requiring periodic replacement as they wear out. This doesn’t mean the tools are of lower quality. Instead, these constraints allow us to streamline the development process, shortening production lead times and reducing costs.

Justo ornare ad elementum aenean lorem penatibus amet consectetuer blandit natoque. Vestibulum tellus felis egestas ullamcorper parturient molestie aenean condimentum.