- Building AB, No. 7 Shiji 2nd Road, Torch Development Zone, Zhongshan City, Guangdong Province, 528437, China.

- enquiry@apt-mold.com

- +86 18814246095

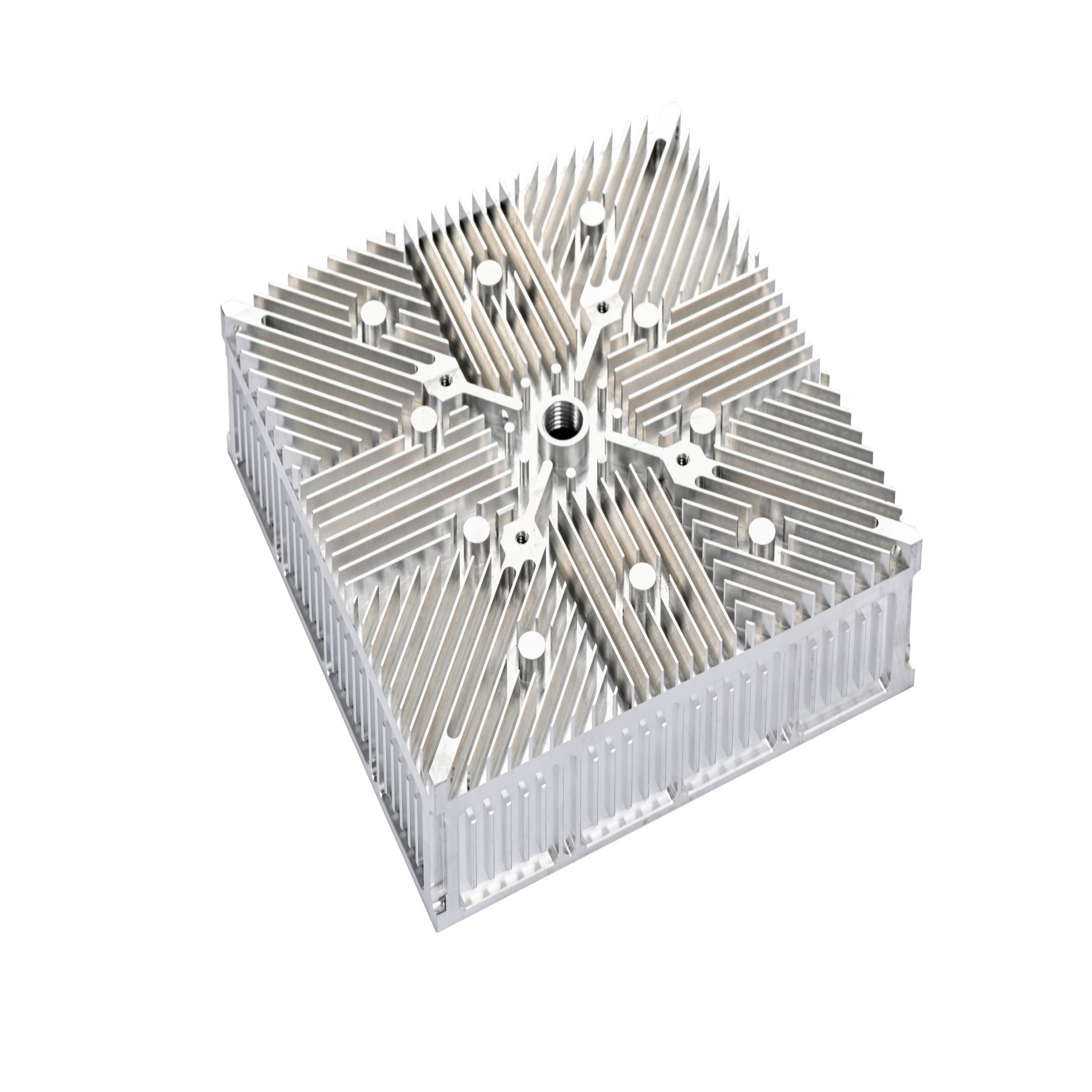

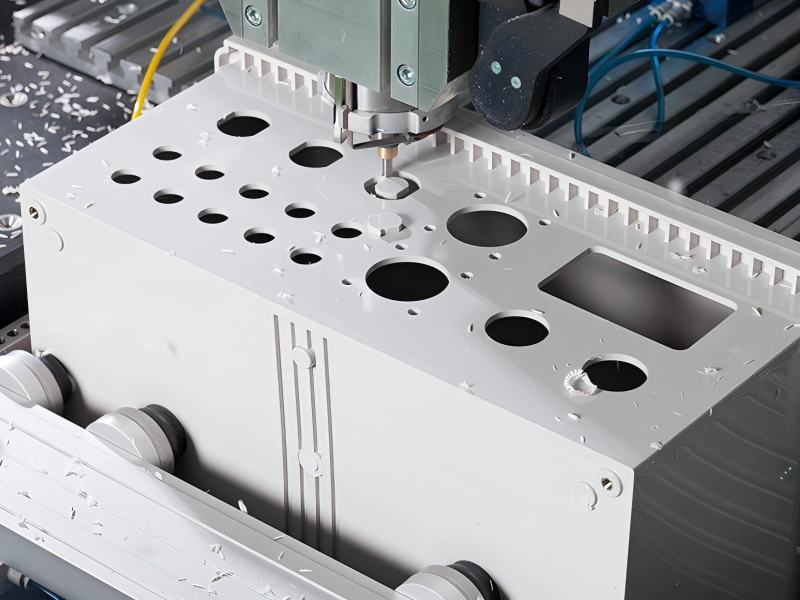

CNC machining is a computer-controlled manufacturing process used to produce custom parts by precisely removing material from solid stock. Using digital CAD designs, machine tools follow programmed instructions to achieve consistent accuracy and repeatability. Suitable for metals and engineering plastics, CNC machining supports complex geometries and tight tolerances. As a result, custom CNC machining services are widely used across aerospace, medical, automotive, and industrial applications.

At APT-Mold, our custom CNC machining services combine speed, precision, and versatility. With access to over 60 engineering-grade plastics and metals, we support diverse needs—from CNC rapid prototyping to low- and high-volume production.

+86 18814246095

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

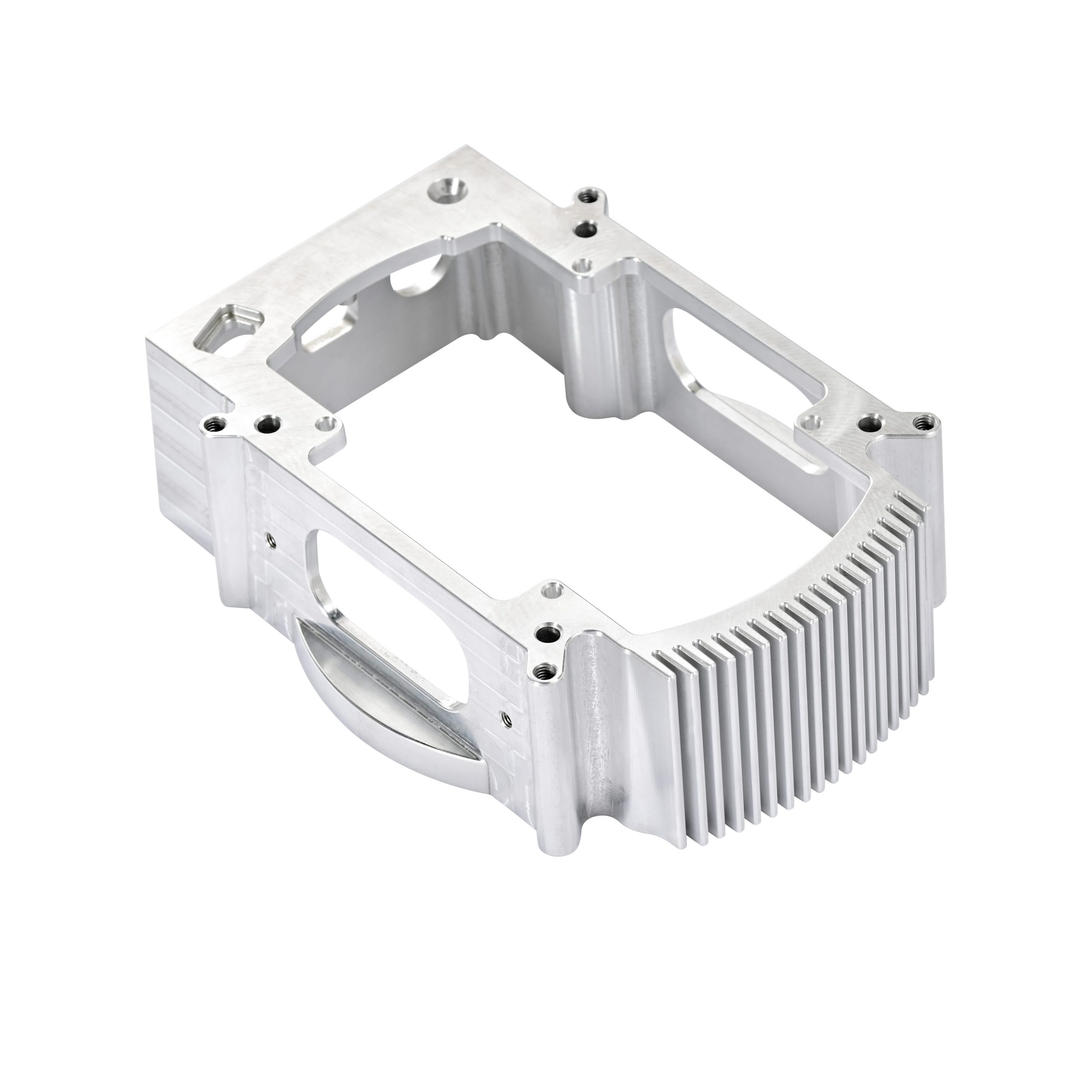

CNC milling is a subtractive manufacturing process that uses 3-axis, 4-axis and 5-axis milling processes to cut solid plastic and metal blocks into final parts.

Our CNC milling process produces custom prototypes and end-use production parts in as fast as a couple of days. We use 3-axis, 4-axis, and 5-axis milling processes to manufacture parts from more than 60 engineering-grade plastics and metals including aluminum, stainless steel, ABS, etc.

For high-volume machined production parts, APT-Mold provides competitive pricing along with first article inspection (FAI) reporting, material certifications, and a range of finishing options, including painting, anodizing, plating, etc.

CNC turning with live tooling combines both lathe and mill capabilities to machine parts with cylindrical features from metal rod stock.

CNC lathes enable precise machining of axial and radial holes, flats, grooves, and slots. We specialize in producing custom CNC prototypes and end-use parts with fast turnaround times, often within just a few days. Our CNC turning services support both small- and large-batch production, delivering accurate and reliable components to meet your needs.

At APT, we deliver custom CNC machining services focused on speed, flexibility, and reliable quality at any production scale. Here’s what makes us different.

Our custom CNC precision machine services are built for tight tolerances and consistent repeatability. Advanced equipment and optimized machining processes ensure every part meets exact specifications.

By optimizing machining strategies and material usage, we help reduce lead times and overall costs. Our flexible production capability supports both rapid prototyping and scalable manufacturing without compromising quality.

Our experienced engineers provide Design for Manufacturability (DFM) feedback to identify potential issues early. From complex geometries to functional optimization, we help refine your designs for efficient CNC production.

Equipped with modern CNC machining centers, we handle simple to complex part designs with confidence. Our capabilities cover rapid machining, low-volume batches, and high-volume production.

We offer over 60 engineering-grade metals and plastics to meet diverse performance and industry requirements, enabling greater flexibility across different applications.

From anodizing and plating to polishing, bead blasting, laser etching, and painting, we provide a full range of finishing options to deliver parts that meet both functional and aesthetic needs.

CNC machining services at APT are structured for speed, flexibility, and superior quality no matter the volume of parts. Here’s what sets us apart.

CNC machining uses pre-programmed computer software to guide machinery, creating precision parts with exact measurements. The machines are meticulously designed for high precision and accuracy.

The high efficiency in material usage, labour costs reduction, and as well as minimized scrap make CNC machining a cost-effective and fast turnaround solution for both one-off prototype and large-scale production.

Our very capable engineers will analyze your part geometry to identify any features that may be difficult to machine and help with trouble shooting by providing you with innovative solutions.

Our highly qualified machine shops can make any custom design, simple or complex. We offer rapid machining, small-batch machining, and high-volume production.

We stock more than 60 engineering-grade plastic and metal materials that are suitable for various part applications and industries.

From bead blasting to polishing, anodizing to plating, laser etching to painting, we offer every surface treatment you need to make a great finished part.

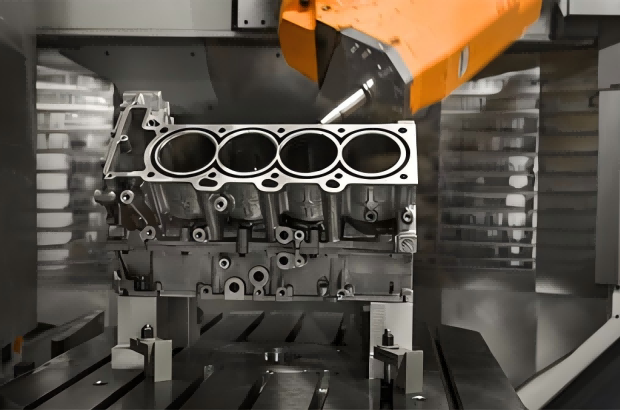

See how various industries use APT-Mold’s CNC machining services to reduce development time, lower production costs, and get to market faster with better products.

Industrial Equipment

CNC rapid prototyping meets the need for fabrication of connected hardware as well as customized components for traditional equipment.

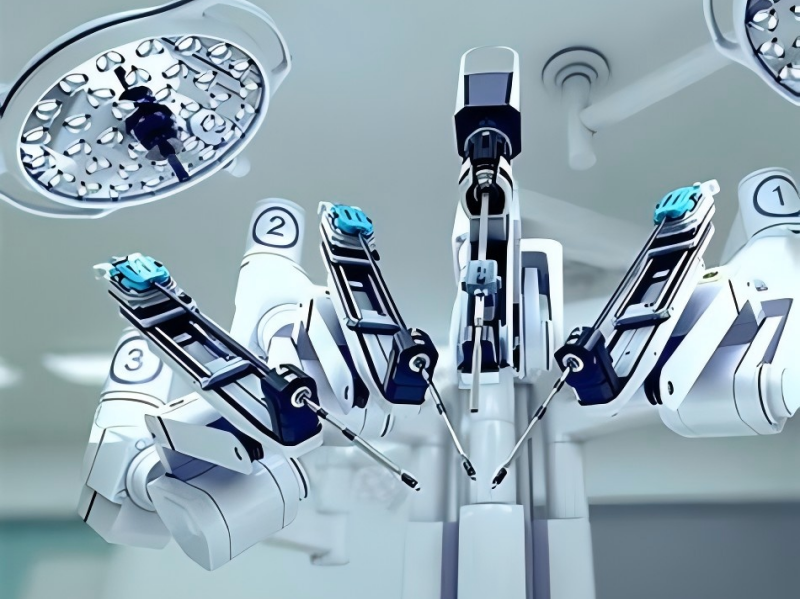

Medical and Healthcare

From connected devices to mass production of health care products, CNC machine service accelerates medical development and market access.

Electronics

Technology-enabled CNC machining processes can accelerate manufacturing cycles, lower development costs, and help support product customization that consumers now demand.

APT-Mold’s custom CNC services support a wide range of materials, from plastics like ABS, polycarbonate, nylon, and PEEK to metals including aluminum, stainless steel, titanium, and copper. We also provide a wide range of surface finishing options like painting, anodizing, plating, etc.

+86 18814246095

Here are the answers to the frequently asked questions. Any other questions, please feel free to contact us at enquiry@apt-mold.com.

CNC (Computer Numerical Control) machining serves as an automated process that transforms solid blocks or rods of material into precise parts using end mills.

CNC machining delivers exceptional accuracy and efficiency, making it ideal for everything from one-off prototypes to mid-volume custom components, outperforming traditional machining methods.

The basic process can be simplified into three main steps. First, a 3D model of the design is created using CAD software. Then the CAD file is converted into a CNC program (G Code) and the machine is set up. Finally, the machine autonomously removes material from the workpiece to form the custom-designed part.

CNC machining prototype service provides high precision, excellent repeatability, and compatibility with a wide range of materials. This makes it ideal for producing functional prototypes and test parts that closely match the performance of the final product.

CNC prototyping service is widely used in industries such as automotive parts, aerospace components, medical devices, electronic housings, and industrial machinery. Whether for single-piece prototyping or small-batch production, it offers great flexibility.

CNC milling mainly uses a rotating cutting tool to shape a fixed part, making it ideal for machining flat surfaces, grooves, and complex geometries. CNC turning, on the other hand, rotates the part itself while the cutting tool removes material, which is best suited for cylindrical or conical components.

Our standard tolerances are ISO 2768(F) for metal parts and ISO 2768 (M) for plastic parts, which is suitable for the majority of commercial and industrial applications. Consult with us if you need tighter tolerances for special projects.

We perform inspections at every step of the product manufacturing journey, from incoming material verification to first article inspection, in-process and final inspection. You will receive complete digital files and Certificates of Compliance so as to meet your regulatory and performance goals.

We guarantee to keep your files and any proprietary information secure and confidential. If needed, we can sign and adhere to your company non-disclosure or confidentiality agreement.

Yes, customer-supplied material is fine as long as it fits with our machine capabilities.

Delivery time depends on the complexity and quantity of the parts. Generally, standard orders can be completed within 3–7 days. With world-class equipment, we provide CNC prototype machining to handle any custom machining requirements.

Justo ornare ad elementum aenean lorem penatibus amet consectetuer blandit natoque. Vestibulum tellus felis egestas ullamcorper parturient molestie aenean condimentum.

Case1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Case2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Case3

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.