- Building AB, No. 7 Shiji 2nd Road, Torch Development Zone, Zhongshan City, Guangdong Province, 528437, China.

- enquiry@apt-mold.com

- +86 18814246095

Sheet metal fabrication is the process of turning flat sheets of steel, aluminium or others into metal structures or products, by cutting, bending, punching and assembling.

With rich experience in sheet metal fabrication service, APT-Mold has been building and creating products for a wide variety of customers and applications, providing high-quality sheet metal parts to customers for over 7 years.

A variety of techniques can be used, making it possible to create complex parts. A wide range of compatible materials can be used for a diverse number of applications.

Sheet metal fabrication allows for easy customization. If the first design/prototype doesn’t work, the part can be easily adjusted, making the creation process flexible and affordable.

Automated metal fabrication machines, which are highly efficient and minimize the need for manual labor, ensure that many manufacturing projects are completed in a short amount of time.

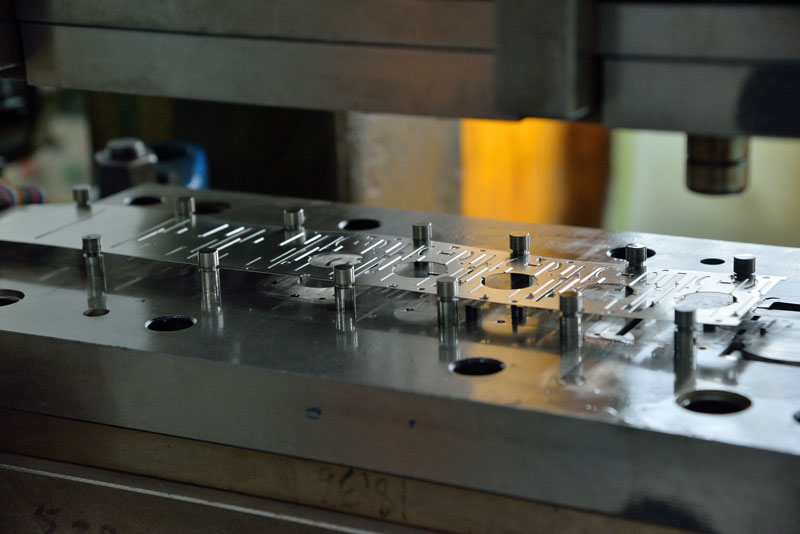

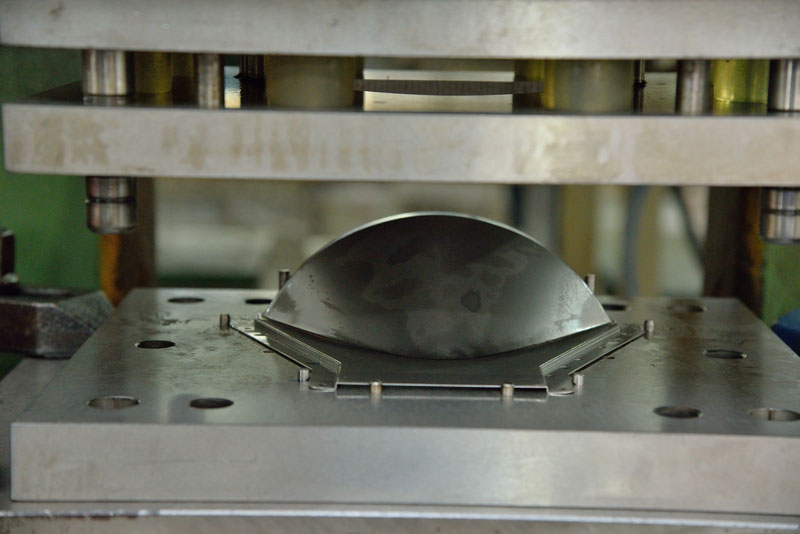

Parts are created through laser cutting, bending, punching with computerized machines capable of forming sheet metal in high quality.

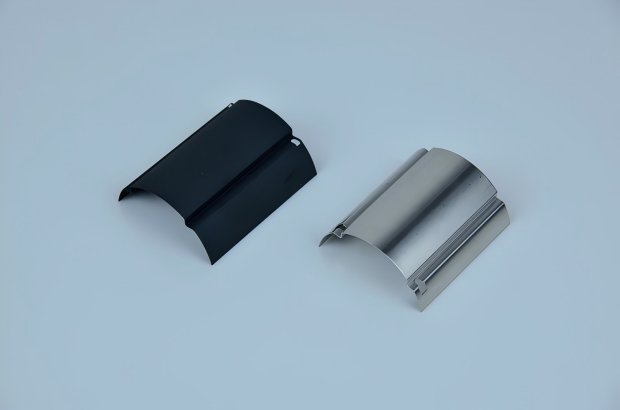

A broad range of surface finishing options such as painting, bead blasting, polishing, grinding and/or brushing make metal sheets a great option in terms of aesthetics.

Sheet metal allows for the manufacturing of products with high wear and tensile resistance compatibility with extreme atmospheric conditions. Technologies such as bending, welding, or heat treatment are commonly used to strengthen the parts mechanically.

Our very capable engineers will analyze your part geometry to identify any features that may be difficult to sheet metal and help with trouble shooting by providing you with innovative solutions.

Sheet metal fabrication service is the perfect solution for creating metal components in both prototyping and production volumes. It offers low material waste, ensuring efficiency and sustainability while remaining cost-effective for a variety of projects. With multiple finishing options like powder coating and anodizing, sheet metal manufacturing service meets both functional and aesthetic requirements. Additionally, its short lead times make it an ideal choice for fast and reliable production.

APT-Mold offers a wide range of technologies and a wide range of compatible materials to create complex parts that can be used in a variety of applications.

Sheet metal fabrication is easy to customize and the creation process is flexible and economical. If the first design/prototype is not feasible, we can easily make adjustments to the part.

Automated metal fabrication machines, which are highly efficient and minimize the need for manual labor, ensure that many manufacturing projects are completed in a short amount of time.

APT-Mold uses computerized machine manufacturing to produce high-quality & precision sheet metal fabrication through laser cutting, bending, and stamping.

A broad range of surface finishing options such as painting, bead blasting, polishing, grinding and/or brushing make metal sheets a great option in terms of aesthetics.

At APT-Mold, Our sheet metal fabrication allows for the manufacturing of products with high wear and tensile resistance compatibility with extreme atmospheric conditions. We utilize precision technologies such as bending, welding, and heat treatment to strengthen the parts mechanically.

With strong technical expertise and advanced manufacturing processes, we provide high-quality, efficient sheet metal fabrication at competitive prices, helping you reduce labor and production costs.

The durability and versatility of sheet metal parts make them a great choice for many industries across the world.

Automotive Industry

From brackets and hinges to metal assemblies for interior trim, we offer a complete manufacturing solution for your vehicle related projects.

Consumer Electronics

he durability and versatility of sheet metal make it a common and critical technique widely used in electronic product like cell phones, drones, computers, audiovisual equipment, etc.

Home Appliance

Sheet metal fabrication brings many benefits like corrosion resistance, durability under different temperature influences and hygiene, making it a go-to choice for home application.

The high efficiency and precision of sheet metal fabrication, combined with APT-Mold’s extensive selection of materials and surface finishing options, ensure that every part meets your exact requirements. With a wide array of surface finishing services, including painting, bead blasting, polishing, grinding, and brushing. Our custom sheet metal fabrication not only delivers exceptional functionality by ensuring durability, precision fitting, and optimal structural integrity but also elevates the aesthetic appeal of your final product.

+86 18814246095

Here are the answers to the frequently asked questions. Any other questions, please feel free to contact us at enquiry@apt-mold.com.

Sheet metal fabrication transforms flat metal sheets into functional components through a 3 steps process.

We are a one-stop sheet metal fabrication company, offering comprehensive assembly solutions, including welding, riveting, fasteners, and adhesives, to meet your specific needs.

Below is tolerance guidance for sheet metal parts at APT

Yes, we provide professional custom sheet metal fabrication services. With advanced manufacturing processes and extensive industry experience, we accurately produce high-quality sheet metal parts, bringing your designs to life while meeting your specific requirements.

Justo ornare ad elementum aenean lorem penatibus amet consectetuer blandit natoque. Vestibulum tellus felis egestas ullamcorper parturient molestie aenean condimentum.

Case1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Case2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Case3

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.