- Building AB, No. 7 Shiji 2nd Road, Torch Development Zone, Zhongshan City, Guangdong Province, 528437, China.

- enquiry@apt-mold.com

- +86 18814246095

Plastic injection molding is a process that utilize the pressure powered by injection machine to inject the hot melted plastics into the tooling, cooling and forming the parts. It is widely used in many industries and helps many parts to achieve the ideal function.

+86 18814246095

Plastic & Plastic over-molding service

Plastic injection over-molding process is widely used on plastic parts with different material or different color, or to achieve specific function. It can not only improves the beauty, comfort and grip of the product and other functions, but also through different molding processes, such as two-color injection molding and secondary injection molding, to achieve the best adhesive effect.

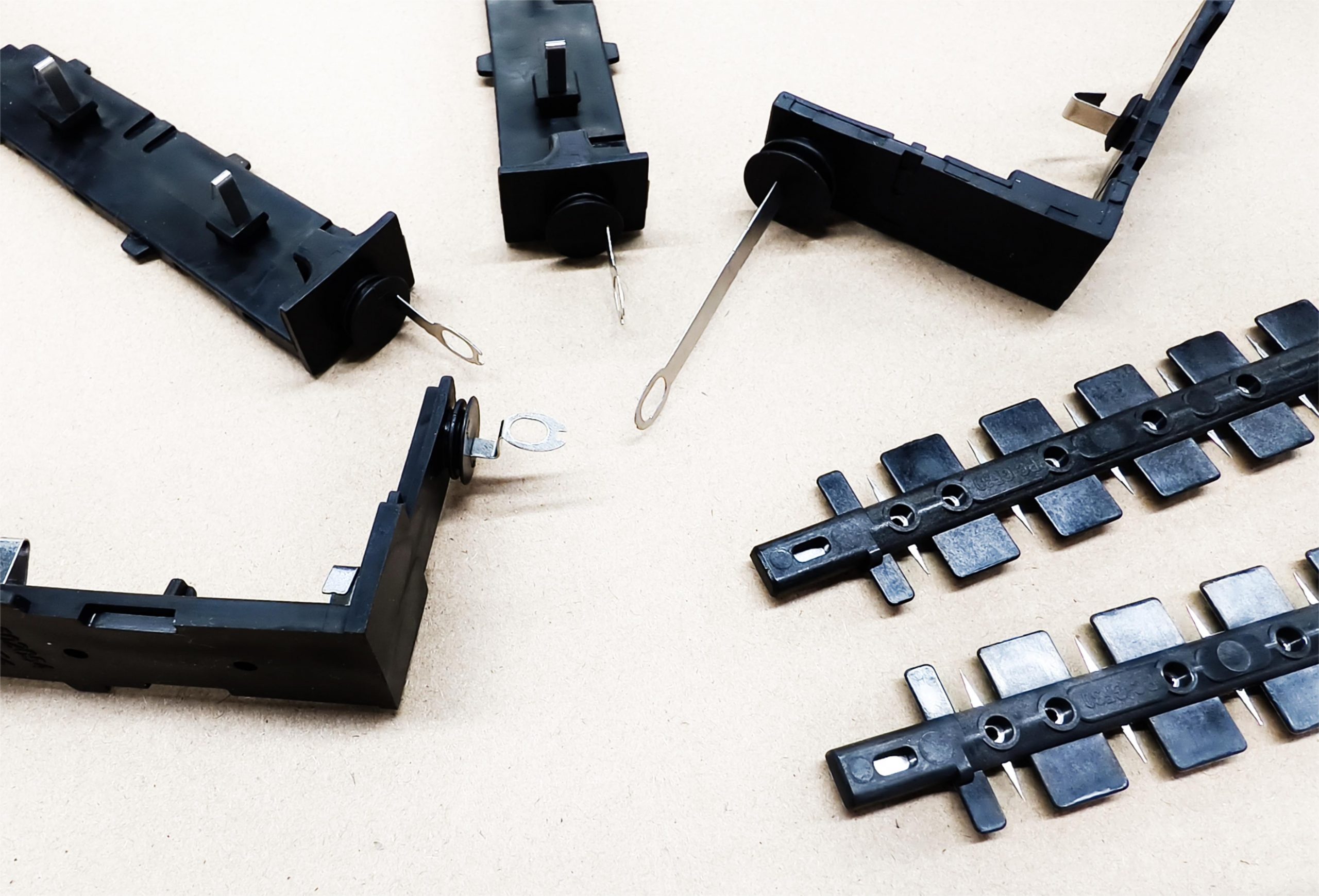

Plastic & Metal over-molding service

The plastic injection molding process combines plastic and metal components. It not only forms a protective layer on the metal surface to improve the durability of the product; it also improves the functionality of the product by providing a non-slip gripping surface, sealing, insulation, or decoration.

APT is experienced in molding production. Once the parameters of the injection molding machine are set, the process can produce a large number of parts in a relatively short time, which is especially suitable for high volume production.

APT assures the quality of your machined parts with our ISO 9001:2015 and IATF 16949:2016 certified quality management system.

APT can produce complex parts with complex shapes and strict tolerances to ensure the accuracy of product dimensions. Our general tolerances are in line with industry standards. The molding plastic parts can reach the tolerance standard of DIN 16901.

APT use automotive manipulator and automotive gate trimming system in the injection molding process, which reduces labor costs and overhead, making it a cost-effective way to produce plastic parts.

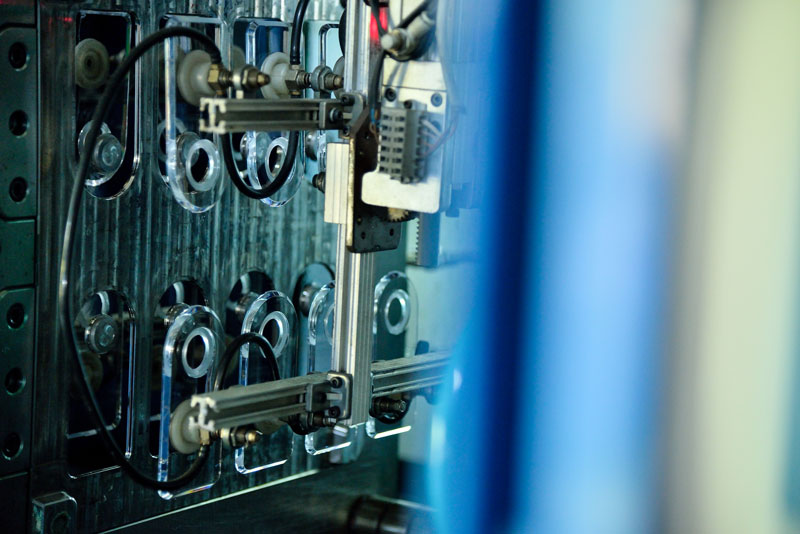

Manufacture the complex parts that the other process may not produce, slide, lifter, hand load insert will be good for your complicated mechanical structure. interchangeable insert will help you save cost.

APT running strictly with quality assurance systems to assure we meet the highest of quality standards. And we have professional measuring equipment such as coordinate measuring machine, image measuring machine and other testing equipment.

APT-Mold is an experienced plastic injection molding company, that specializes in producing high-quality injection molded parts quickly and efficiently, making it ideal for high-volume production.

APT assures the quality of your machined parts with our ISO 9001:2015 and IATF 16949:2016 certified quality management system.

Our injection molding services are capable of producing complex parts with intricate shapes and tight tolerances. We adhere to industry-standard general tolerances, with plastic parts meeting DIN 16901 tolerance requirements.

With automated manipulators and an automated gate trimming system, APT-Mold's plastic injection molding service helps reduce labor costs and overhead, providing a cost-effective solution for producing plastic parts.

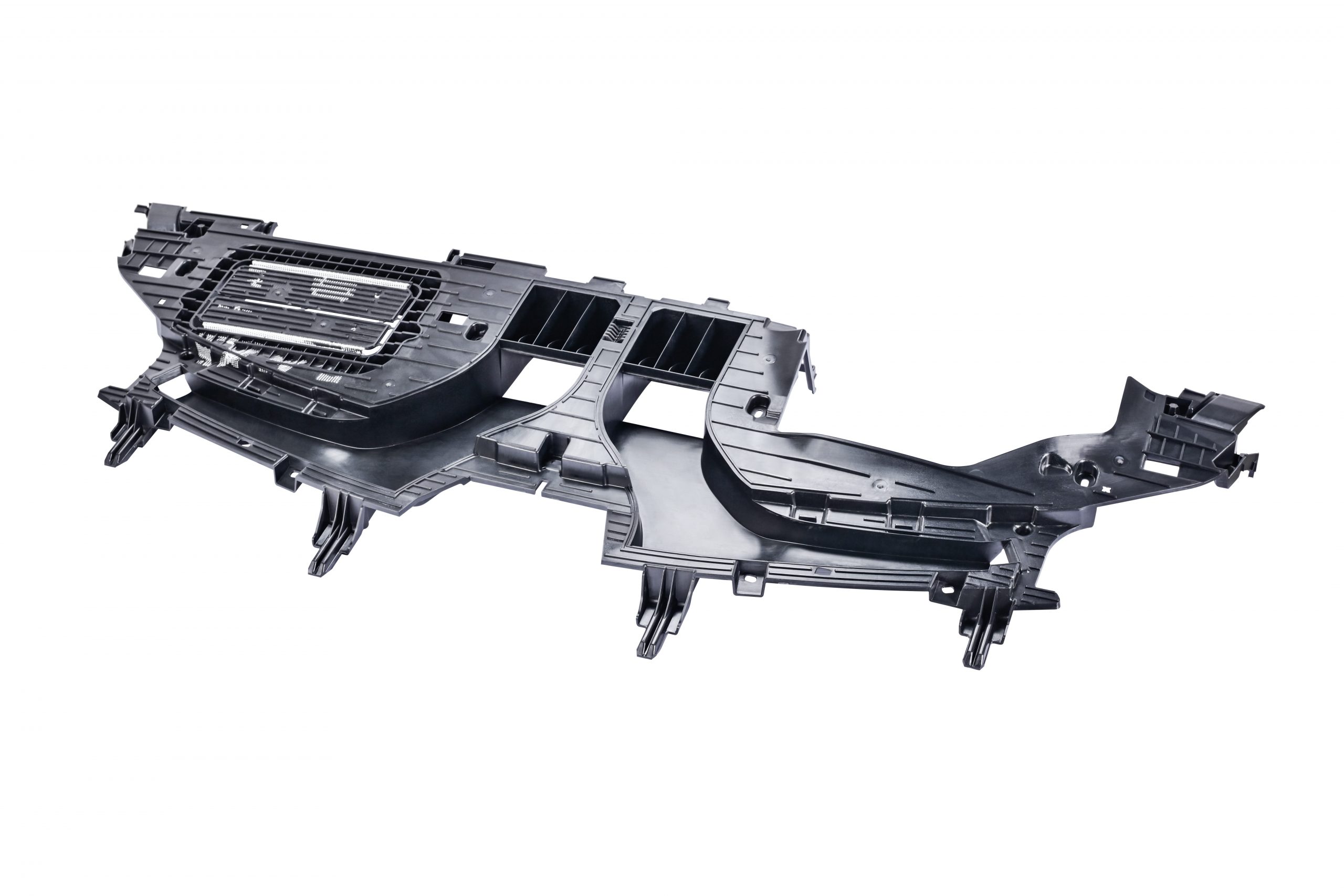

APT-Mold's custom plastic molding is a great solution for producing complex parts. This approach adapts to intricate mechanical structures, including sliders, lifters, manual loading inserts, and interchangeable inserts.

APT-Mold operates under strict quality assurance systems to ensure we meet the highest standards. We are equipped with professional measuring tools, including coordinate measuring machines, image measuring machines, and other advanced testing equipment.

Injection molding technology with its high efficiency, high precision, material diversity, cost effectiveness, design and manufacturing flexibility, lightweight and environmental protection, play an important role in modern manufacturing.

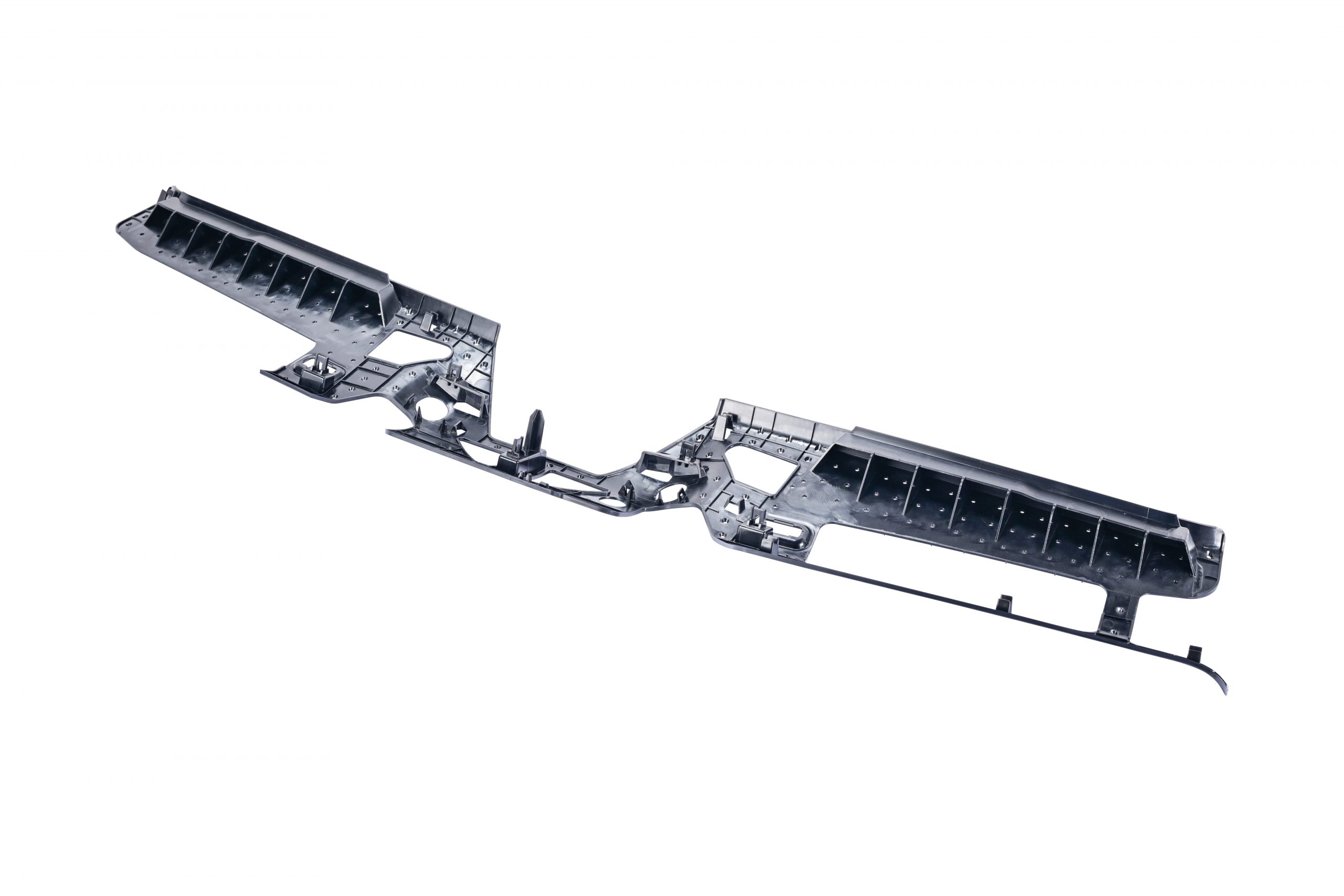

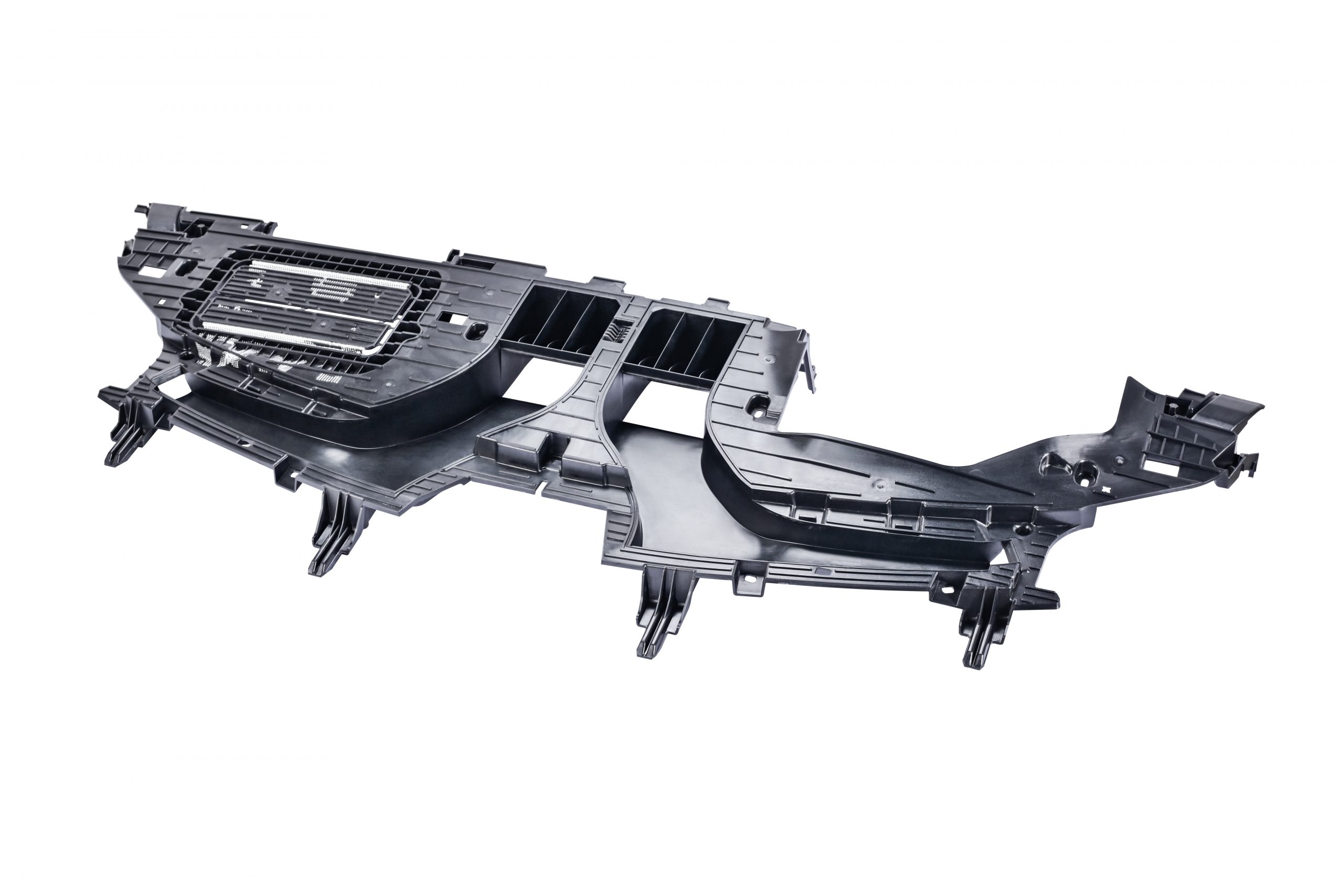

Automotive and Transportation

The automotive industry is one of the important application fields of injection molding process. It is used in the manufacture of various automotive components. These plastic parts help reduce vehicle weight and improve fuel efficiency.

Medical and Healthcare

In medical device manufacturing, injection molding process is used to manufacture various medical devices, syringes, infusion bags, medical equipment shells, etc. These plastic parts are essential for the proper functioning of medical devices and the health of patients.

Electronics and Appliances

The injection molding process plays an important role in the electronics and appliances industry, mainly used to manufacture housings, connectors, cables and other plastic parts for various devices.

Materials available range of plastics like ABS, Polycarbonate, nylon, Polypropylene, thermoplastic urethane, etc. We also provide a wide range of surface finishing options like polishing, texture, painting, plating, etc.

+86 18814246095

Here are the answers to the frequently asked questions. Any other questions, please feel free to contact us at enquiry@apt-mold.com.

Plastic injection molding is a process that injects molten plastic resin into a custom mold under high pressure. Once cooled, the hardened part is ejected, and this process can be repeated multiple times, reducing costs for high-volume production. Unlike CNC machining, this method accommodates a broader spectrum of materials, including high-performance engineering plastics, and offers extensive customization options in colors, surface finishes, and intricate geometries.

With our plastic injection molding service, you can achieve consistent quality, tight tolerances, and efficient production for automotive, electronics, medical devices, and consumer goods.

APT-Mold can analyze the cost of plastic injection molding parts with the DFM process, we can help you identify and address potential costs in the part’s production.

APT-Mold can analyze the cost of plastic injection molding parts with the DFM process, we can help you identify and address potential costs in the part’s production.

Our general tolerances are in line with industry standards. The molding plastic parts can reach the tolerance standard of DIN 16901. Other special requirements can have a discussion based on the products structure.

Yes. We have packaging & assembly department, which is experienced in some assembly products. Also we have equipment such as ultrasound machine and auto screw machine which can help to do assembly.

Justo ornare ad elementum aenean lorem penatibus amet consectetuer blandit natoque. Vestibulum tellus felis egestas ullamcorper parturient molestie aenean condimentum.