- Building AB, No. 7 Shiji 2nd Road, Torch Development Zone, Zhongshan City, Guangdong Province, 528437, China.

- enquiry@apt-mold.com

- +86 18814246095

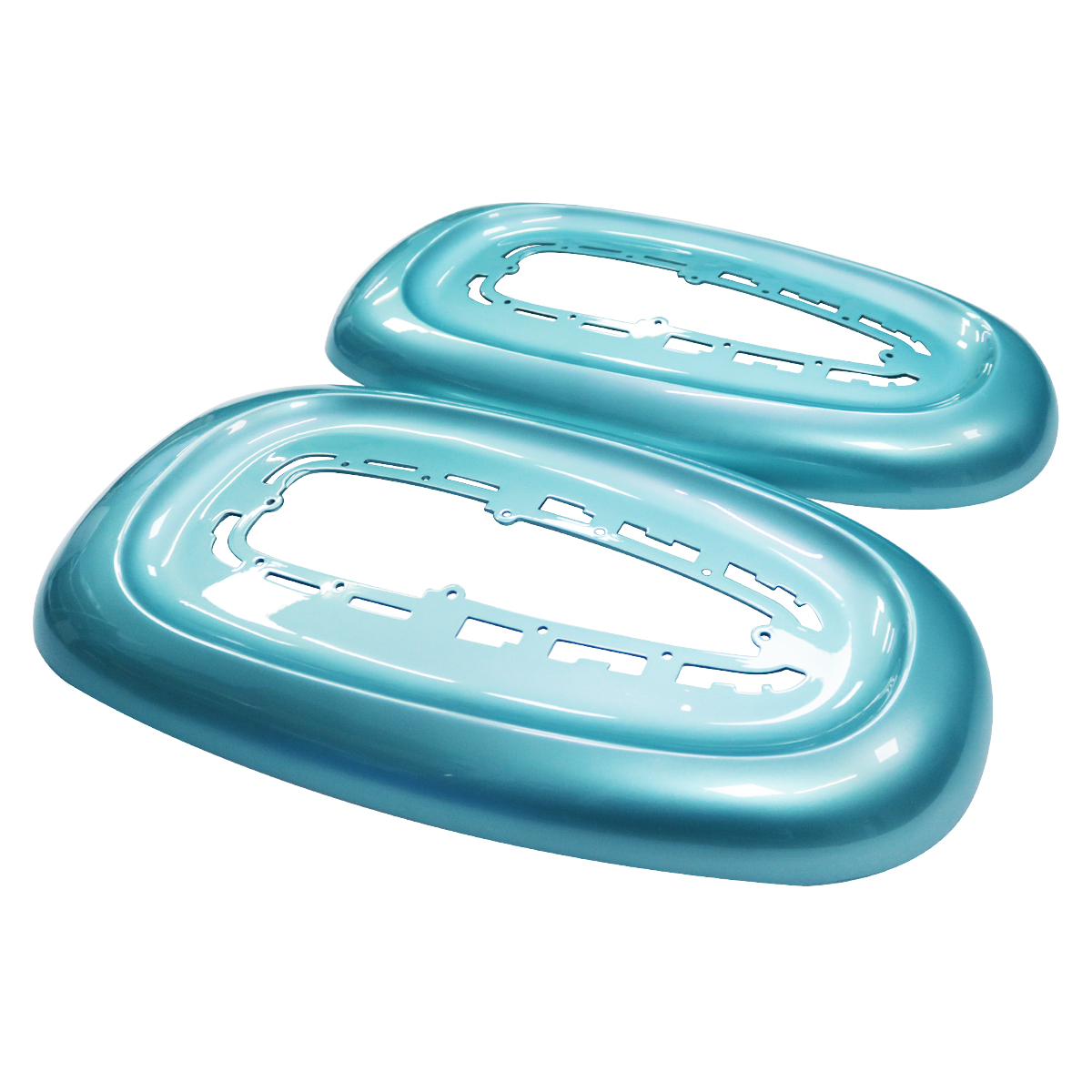

Vacuum Casting, sometimes called Urethane or Polyurethane casting, uses silicone molds and vacuum pressure to produce plastic and rubber parts with exceptional detail. Unlike traditional plastic injection molding, this vacuum casting service doesn’t require expensive metal tooling, making it a faster, more cost-effective option for producing complex prototypes or low-volume runs.

By closely replicating surface textures, material properties, and fine features, vacuum casting provides an adaptable solution that streamlines product development and testing.

APT offers end-use, rigid plastic, rubber-like, and silicone parts with production-grade quality to fit your timeline and budget

Our customers use vacuum casting to create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.

Comparing to steel mold for injection molding, the inexpensive silicone molds vacuum casting the parts demonstrate the same quality while taking only a fraction of the time, typically in 2 or 3 days.

There are various material options available such as clear, rubbery, flame retardant and food grade to fulfill your needs. We can also add glass fibers to increase the stiffness of ABS and nylon for even more design options.

APT offers a wide range of complementary finishing services to help your product come to life. Our finishing services include media blasting, printing, painting and more.

Vacuum Casting is a perfect alternative for insert molding or overmolding in low volumes with diverse material choices.

Our very capable engineers will analyze your part geometry to identify any features that may be difficult to vacuum casting and help with trouble shooting by providing you with innovative solutions.

Vacuum casting service delivers exceptional advantages for rapid prototyping and low-volume production needs. This cost-effective process achieves high-quality results, producing parts with superior surface finish and precise detail reproduction. Vacuum casting also accommodates diverse engineering resins with customizable properties, by offering extensive material versatility. From color matching to surface textures, this process ensures your prototype parts meet exact design specifications and performance requirements.

APT-Mold offers end-use, rigid plastic, rubber-like, and silicone parts with production-grade quality to fit your timeline and budget.

Our vacuum casting services deliver premium-quality parts for showroom displays, engineering prototypes, and crowdfunding projects, perfect for small-batch production needs.

APT-Mold’s vacuum casting service uses silicone molds to deliver high-quality parts in just 2-3 days, offering faster turnaround and greater cost efficiency than steel molds.

There are various material options available such as clear, rubbery, flame retardant and food grade to fulfill your needs. We can also add glass fibers to increase the stiffness of ABS and nylon for even more design options.

APT offers a wide range of complementary finishing services to help your product come to life. Our finishing services include media blasting, printing, painting and more.

Vacuum Casting is a perfect alternative for insert molding or overmolding in low volumes with diverse material choices.

Our professional engineers will analyze your part geometry to identify any features that may be difficult to vacuum cast and help with troubleshooting by providing you with innovative solutions.

See how major industries use vacuum casting to create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.

Automotive Industry

An ideal rapid prototype service when preparing a product such as dashboards, door handles, light covers, air vents, etc. for high volume production, especially with injection molding.

Consumer Electronics

From show-room quality display models to end-use products, vacuum casting accelerates product development and market introduction.

Medical and Healthcare

Vacuum casting has a lot to offer the medtech industry, design flexibility, affordability, and a short time-to-market, to support customers innovate successfully.

Selecting a suitable vacuum casting material and surface finish is essential for creating high-quality castings. APT provides various material options such as clear, rubbery, flame retardant and food grade along with a wide range of surface finishing options like media blasting, printing, painting and more to fulfill your needs.

+86 18814246095

Here are the answers to the frequently asked questions. Any other questions, please feel free to contact us at enquiry@apt-mold.com.

Vacuum casting works in a way similar to traditional injection molding where it requires a mold with a part shaped cavity. The injection mold tools are made of metal (steel, aluminum, etc.), while vacuum casting uses soft silicone molds.

There are three steps to making polyurethane vacuum casting parts:

Vacuum casting is ideal for low-volume production, typically 10–500 parts, and in some cases up to 1,000 units. It’s widely used for functional prototypes, bridge production, and market testing. Vacuum casting services offer a cost-effective alternative to injection molding, with minimal tooling investment.

Vacuum-cast parts are very similar to injection-molded parts in appearance, fit, and function. Using high-quality silicone molds and urethane resins, a professional vacuum casting manufacturer can achieve excellent surface finish and dimensional accuracy, making them suitable for functional testing and end-use evaluation.

Choose vacuum casting when you need multiple parts with consistent quality, better surface finish, and lower cost per unit than CNC machining or 3D printing. Compared with additive manufacturing, urethane casting service delivers injection-molded–like results, making it ideal for small-batch production and pre-series validation.

We offer vacuum cast parts that are typically +/-.010” for the first inch and +/-.005″ per inch thereafter. However,irregularly shaped or excessively thick geometric parts may be subject to deviation or distortion due to material shrinkage.

Surface finish is externally smoothed to a satin or matte surface. Grow lines may be present on internal or difficult-to-access features. Polishing or custom finishes must be clearly defined and agreed upon before production released.

We perform inspections at every step of the product manufacturing journey, from incoming material verification, first article inspection for both master patterns and castings, and in-process and final inspection. You will receive complete digital files to meet your goals. As a certified vacuum casting factory with ISO 9001 and IATF 16949 certifications, we are a trusted partner committed to delivering precision and reliability in every project.

Currently, APT-Mold does not provide design services. To use our vacuum casting service, you’ll need to supply 3D CAD designs or a suitable physical sample. However, we do offer custom vacuum casting solutions tailored to your specific needs, ensuring high-quality results that meet your requirements.

Justo ornare ad elementum aenean lorem penatibus amet consectetuer blandit natoque. Vestibulum tellus felis egestas ullamcorper parturient molestie aenean condimentum.

Case1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Case2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Case3

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.