Finishing is what gives a CNC-machined part its final look and ensures it performs as intended. In CNC machining, “finish” usually refers to two things. First, the surface roughness that remains after cutting — the as-machined quality. Second, the post-machining treatments, such as anodizing, plating, polishing, or bead blasting, enhance both appearance and performance. This scope closely aligns with industry standards for surface texture and roughness.

Why does it matter? Because finish isn’t just about looks. It affects friction, wear, sealing, corrosion resistance, and overall durability. In this guide, we’ll break down CNC surface finishes and machining treatments to help you make informed choices.

Table of Contents

ToggleWhy CNC Finishes Matter

A CNC surface finish affects how a part performs and looks. Here’s why finishes are so important:

- Corrosion resistance

Protective layers, such as stainless steel passivation or aluminum anodizing, shield parts from rust and chemical damage.

- Wear resistance

Lower roughness reduces friction and wear.

Hard coatings or surface treatments add durability for heavy-use applications.

- Aesthetic appeal

Finishes can transform appearance with colors (anodized dyes, fades) or textures (matte bead blasting, powder coating).

- Assembly precision

Coatings add thickness, and surface roughness affects how parts fit and seal together. Proper finishing ensures tight tolerances and smooth assembly.

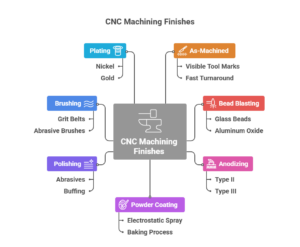

Common CNC Machining Finishes

As-Machined

This is the bare cut from the tool, with visible tool marks. The surface is functional and clean, and the default roughness is about Ra 3.2 µm (125 µin). A finishing pass can reduce it to 1.6, 0.8, or even 0.4 µm, but tighter roughness requires more machining time and closer control. Use this finish when you want the default CNC surface finish and a fast turnaround.

Bead Blasting

Bead blasting shoots media at the part to even out small nicks and lines, giving the surface a uniform, matte appearance. Glass beads are gentle and clean the surface, while aluminum oxide media is more aggressive, roughening the surface for later coatings.

This process is commonly used before anodizing to achieve a consistent tone. A CNC surface finish created by bead blasting is especially useful in applications where glare is a problem.

Anodizing

Anodizing forms a controlled oxide layer on metals, most commonly on aluminum. Type II anodizing offers color options and moderate wear resistance, with a thickness of up to 25 µm[1]. Type III is harder and thicker (over 25 µm), providing greater wear resistance. This CNC surface finish enhances both corrosion protection and the ability to absorb dyes.

Powder Coating

Powder is sprayed onto a grounded part using an electrostatic gun, causing the charged particles to cling to the surface. The part is then baked to melt the powder and cross-link it into a durable film. The resulting dry film is usually 60–120 µm thick, forming a tough, colored shell that provides good coverage even on edges. This CNC surface finish is particularly suitable for enclosures and brackets.

Polishing

Polishing uses abrasives to reduce surface peaks, while buffing enhances the shine. Polishing is the more aggressive step, and buffing is gentler, brightening the surface. Mirror-like finishes can achieve very smooth surfaces, with roughness values typically around 1-12 Ra µin[2]. Use this when optics or easy cleaning matter.

Brushing

Brushing creates fine, directional lines on the metal, producing a uniform, satin-like texture. It helps reduce glare and hide small imperfections, while also assisting in deburring and breaking sharp edges.

Grit belts or abrasive brushes are typically used for the process, and both stainless steel and aluminum respond well to it. It’s important to specify the grain direction to match how the part will be viewed or used.

Plating

Plating deposits a metal layer on the part to enhance appearance, wear resistance, or corrosion protection. Nickel is commonly used as a barrier and leveling layer, while gold is applied on contacts for low resistance and stable conductivity.

The performance depends greatly on the plating thickness and alloy choice; for example, zinc-nickel can provide 2–3 times[3] better corrosion resistance than plain zinc. When designing parts with tight fits, be sure to account for the added thickness from the plating.

How to Choose the Right Finish

Functionality

Pick a CNC surface finish that matches the job. For corrosion on aluminum or titanium, anodizing works well. Type II helps with corrosion, while Type III adds higher wear hardness. Keep in mind that the oxide layer is non-conductive.

Need conductivity on aluminum? Go for chromate conversion. Want hard, uniform wear resistance on many metals? Electroless nickel does the job.

Aesthetics

Decide how you want it to look. For instance, bead blasting provides a uniform matte or satin impression and helps hide tool marks. On the other hand, for color, anodizing can be dyed before sealing. Prefer a visible grain? Brushing makes a straight, directional texture.

Budget

Keep costs low with as-machined—it needs no extra steps. For a mid-level budget, consider brushing or bead blasting; they add some time but are still moderate. The highest costs come with anodizing or plating, and Type III anodizing can be the priciest among common finishes.

Choosing CNC Finishes by Material

| Material | Recommended Finishes | Benefits | Typical Applications |

| Aluminum | • Anodize Type II (colored) • Anodize Type III (hardcoat) • Bead blasting (pre-anodize) • Powder coat | • Corrosion & wear resistance (Type II) • High hardness & insulation (Type III) • Uniform matte texture (bead blast) • Durable topcoat (powder) | • Consumer electronics housings • Outdoor gear • Aerospace/auto brackets • Enclosures |

| Stainless Steel | • Electropolishing (ASTM B912) • Bead-blasted / Brushed / Polished • PVD coatings (TiN) | • Smoother, cleaner surface (electropolish) • Controlled textures for aesthetics • Improved wear & hardness (PVD) | • Food and medical equipment • Instruments • Marine/outdoor hardware • Cosmetic panels |

| Brass & Copper | • Tin plating • Nickel or nickel-chrome plating • Clear lacquer / protective coat | • Conductivity & corrosion protection (tin) • Increased hardness & decorative finish (nickel/chrome) • Tarnish/corrosion protection without major dimensional change (lacquer) | • Electrical connectors & busbars • Decorative hardware/plumbing trim • Architectural accents |

| Titanium | • Color anodizing (Type III) for identification • Type II anodizing for corrosion/galling resistance • Bead blasting for matte | • Excellent corrosion protection & color coding (anodize) • Uniform non-glare texture (bead blast) | • Medical implants & fasteners • Aerospace hardware • High-end consumer parts |

| Plastics | • Vapor polishing (PMMA/PC) • Flame polishing (acrylic) • Bead blasting • Hand polishing / tumbling | • Optical clarity & removal of machining marks (vapor/flame polish) • Matte/frosted cosmetic texture (bead blast) • Deburr & smooth in batches (tumbling) | • Light pipes/lenses • Display windows & covers • Cosmetic housings |

Choosing CNC Finishes by Industry

- Aerospace:Flight parts face corrosion, heat, and wear. The CNC surface finish follows MIL-PRF-8625 hard anodize or MIL-DTL-5541 Chem-Film. That also boosts paint adhesion and preserves conductivity. Hardcoat adds wear resistance and insulation.

- Medical:Devices must be uncontaminated, clean, and safe in the body. Polishing eradicates tool marks. Similarly, electropolishing lowers roughness and boosts corrosion resistance.

- Consumer Electronics:Casings need a uniform matte look that colors well. Bead blasting gives an even texture. Then, anodizing provides color and abrasion resistance.

- Automotive:Trim must look good and survive weather. For that purpose, brushed stainless (#4) hides fingerprints on handles and strips. On the other hand, polished pieces might use nickel-chrome for brightwork and corrosion protection.

Partner with APT-Mold for High-quality CNC Machining Service

With so many CNC machining surface finishes to choose from, and each industry having its own requirements, you might feel unsure about which option is right for your parts. A wrong choice could affect your product’s performance or appearance. That’s why having the right partner matters.

APT-Mold can guide you through the CNC machining process. We offer 3- to 5-axis CNC milling and turning for metals and plastics, from prototypes to mass production. With over 60 engineering-grade materials and a full range of surface finishes, including bead blasting, polishing, anodizing, plating, laser etching, and painting, we help you create parts that perform reliably and look great.

Our engineers provide DFM support and technical guidance, spotting potential issues before production so you avoid costly mistakes and delays. Combined with precision machines and efficient workflows, we deliver parts on time and to exact specifications.

Explore what we can do, and see how we can make your next CNC project smooth and worry-free.

References

[1].Anodizing. Available at: https://en.wikipedia.org/wiki/Anodizing. (Accessed on September 22, 2025)

[2].Automated Surface Finishing Processes in Manufacturing. Available at: https://deburringtechnologies.com/surface-finishing-processes-in-manufacturing/. (Accessed on September 22, 2025)

[3].What Engineers Should Know about Zinc-Nickel Coatings. Available at: https://www.machinedesign.com/materials/article/21835189/what-engineers-should-know-about-zinc-nickel-coatings. (Accessed on September 22, 2025)