We are taking a little time away from technical issues to discuss one of the most misunderstood logistics procedures in the prototype molding industry. Today we are talking about Lean manufacturing and how American manufacturers have poorly perceived this idea while their Asian competitors have embraced the right approach. This is essentially the reason why the Chinese and Japanese manufacturing industries have overtaken the industry while keeping the lows costs they are famous for. Let’s start with the basics of “Lean”. As you probably expect the concept of Lean manufacturing is closely related with the idea of having fewer people doing more.

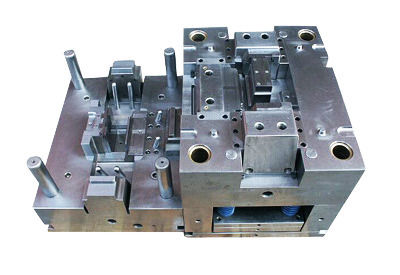

prototype molding, *picutre from indiamart.com

Lean or How to do More with Less

While in fact, the basic idea is there the approach involves a lot more. Lean manufacturing is closely tied to the Just-In-Time manufacturing process created in Asia nearly ten years ago. The logistics method where put in place by many companies in the continent to improve the quality of their products, at lowers risks for their companies, thus building a more solid manufacturing machine at the expense of a minor and more realistic inventory. When American companies got a hold of this method, they merely used it to lay-off personnel and injected their overstocked product into the supply chain. Not only it’s an impractical method of work it’s also unethical.

How Lean Works (and How It Doesn’t)

Lean Manufacturing requires an entirely different outlook on industry standards. While it’s true that the logistics methods help save a lot of money, it’s also a fact that it demands a little investment that will save money to the company in the long run. A manufacturing operation planning on switching to Lean methods needs better technology that can handle more tasks without human supervision. It also demands better-trained employees that know what they are doing. Having six technicians working a production cycle on a failing product using a bad prototype molding is the complete opposite of Lean. The perfect set-up boils down to the ability of the business owner to get a full view of the things he needs to make his operation self-sustainable. Lean requires a proper study of the market and a comprehensive analysis of the type of projects your company can handle. After comparing your success rate with failed or unsatisfied clients, you will have a pretty clear idea about how to accurately aim your efforts. This data can also give you a good idea about the type of technology you can invest in, as well as the training your employees will need.

Closing Thoughts

The most successful Lean manufacturing is the one that can apply the “lights-out policy” created by the Japanese. Manufacturing companies using the right Lean approach needs minimal human intervention since most of the tasks are performed by technology. The human shifts are solely focused on handling the technical aspects that need to be programmed on the machines. China has so many prototype molding manufacturers looking to earn a spot in a saturated market that they have become masters at using the Lean approach to save costs. Americans certainly could learn a thing or two about them.