What is CNC Machining?

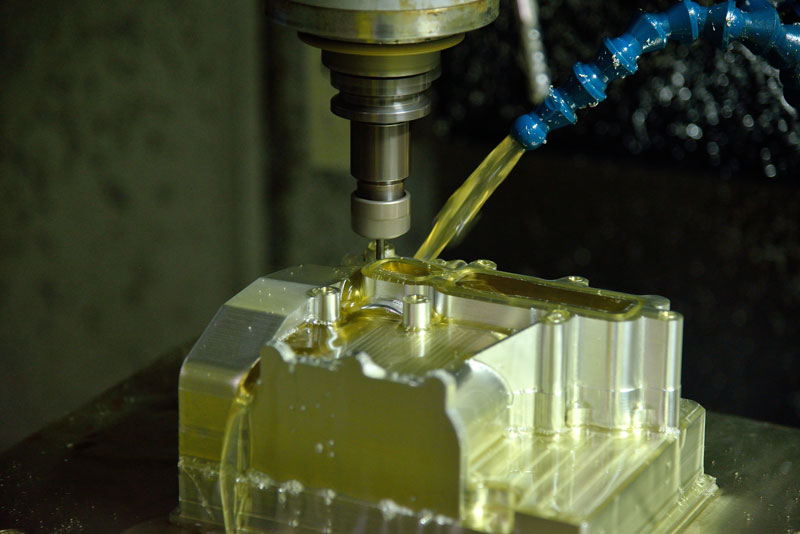

APT-Mold focused on CNC machining for many years. For prototype quantities of customized metal and plastic parts, CNC Machining costs shorter time than tooling, which is the best way to match proposed production-part properties in early development. We take your 3D CAD model and create precision CNC (Computer Numerically Controlled) machining paths that guide our equipment to follow every contour and hole. The result is a precisely replicated part, exactly matching your original design.

Rapid CNC Machining

For prototype quantities of custom metal and plastic parts, CNC Machining is often the best process, short of tooling, to match proposed production-part properties. We take your 3D CAD model and create precision CNC (Computer Numerically Controlled) machining paths that guide our equipment to follow every contour and hole. The result is a precisely replicated part, exactly matching your original design.

When should I consider Rapid CNC Machined prototype parts?

You should choose Rapid CNC whenever you require parts in the exact material you plan on using in production. Other rapid prototype processes can often simulate the final material, but we know there are times when substitution is just not an option.

Can you also provide machined parts in production quantities?

Yes, we can! APT can help you reduce product costs and increase your competitive edge by utilizing our automated CNC machining capabilities. We are committed to provide you with the best machined products and services at the most competitive prices.

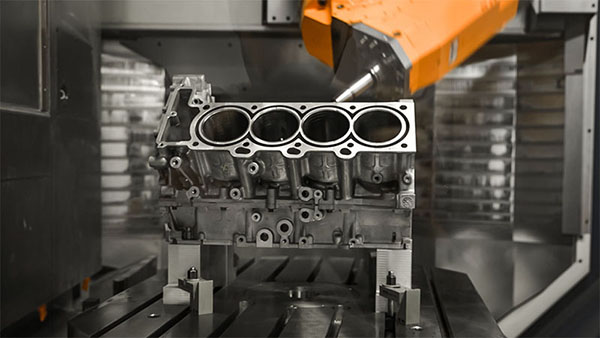

APT’s capabilities include CNC Machining, CNC Milling, CNC Turning, and High-Precision CNC Machining.

Materials:

The type of rigid materials available when using the CNC Machining process are virtually unlimited. We can source whatever materials your design requires. Some of the most common materials we utilize are:

Plastics: ABS, Polypropylene, PMMA ( like Plexiglas® acrylic), PC (polycarbonate, Lexan®), Nylon, POM (Delrin® acetal), and more. Check out the prototyping properties of plastics. Contact us about other possibilities.

Metals: Aluminum, Low-Carbon Steel, Stainless Steel, Brass, Copper, and more. Check out the prototyping properties of metal. Contact us about other possibilities.

Why Choose APT For CNC Machining

√Complete services

APT’s capabilities: CNC Machining, CNC Milling, CNC Turning & CNC Grinding.

CNC turning is the ideal way to make deep holes, machined threads, and all types of cylindrical shapes that have superior surface finishes. CNC milling makes complex prismatic shapes and flat surfaces for a limitless variety of commercial and industrial products. EDM Controlled pulses of electricity are used to erode even the hardest metals with great precision. CNC Grinding is the best way to make a extremely flat surface.

√High-precision tolerances

The general Tolerance of our CNC machining metal parts is DIN ISO 2768-1-fine. The general Tolerance of the plastic parts is DIN ISO 2768-1-medium. If our customers have other special requirement on tolerance, our engineer will also communicate well with the customer and realize it until the customer is satisfied to the product.

√Competitive price

We uphold the belief of reducing costs for our customers and extend our company. So we always quote the price with smallest profit and devote to keep more long term customers.

√Material unlimited

The type of rigid materials available when using the CNC Machining process are virtually unlimited. We can source whatever materials your design requires. Some of the most common materials we utilize are:

Plastics: ABS, Polypropylene, PMMA ( like Plexiglas® acrylic), Nylon, Check out the prototyping properties of plastics. Contact us about other possibilities.

Metals: Aluminum, Low-Carbon Steel, Stainless Steel, Brass, Copper, and more. Check out the prototyping properties of metal. Contact us now!

√Short lead time

We can finish a part within one day or two. And we can machining parts from simple structure to complicated, from small size to large. We handle the process strictly so that we can finish the projects effectively and shorten the lead time.

√Experience Team

We have made countless parts for various industries. The parts used on automobile, bicycle, health testing instrument, earphone, mobile phone, charger, refrigerator, faucet, lock,and so on. We are glad to know that your product is not what we did before. Because our engineer will be more focused on new products.

Advantage of CNC Machining

CNC machine tools are controlled by program instructions, the whole process of processing is automatically carried out according to the program instructions. CNC machining procedures not only include parts of the process, but also includes the process parameters necessary to complete the process, such as cutting dosage, feed route, tool size number and machine tool movement process. It can process complex surface which is difficult to be processed by conventional methods, and even some parts which cannot be observed.

- High efficiency

- High processing accuracy

- Low labor intensity

- Unlimited volume

- Highly intelligent in complex workpiece

- Strong adaptability to different workpiece

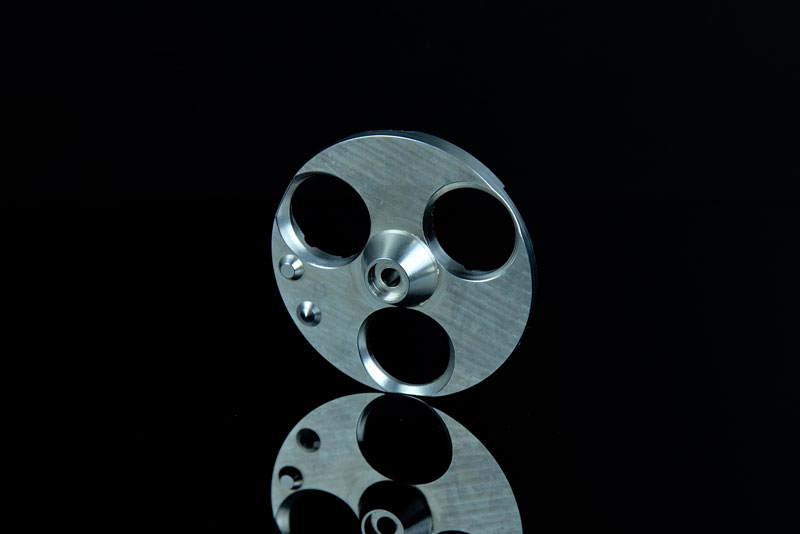

Sample Our Work

At APT Mold, we have experience making highly cosmetic parts (exterior housings, lenses, etc.) as well as less visible mechanical parts (chassis, brackets, gears, etc.). We service markets ranging from industrial to home appliance, from automotive to consumer products, and from medical to scientific.

Please review the following portfolio of parts and products to see the breadth and quality of our work.

Technical Support

The support from APT team will help you shorten the lead time and cost saving in new product development. We will support your project design for manufacturing.

Innovative Ideas

We have innovative ideas based on design. Our manufacturing experience will help you trouble shooting and turn your idea into reality, get things done.

Advanced Technology

Our rapid prototyping technology in Computer Aided Design(CAD) and Computer Aided Manufacturing(CAM) also with experienced technician will make the parts in high quality.

Fast Response

We keep a close eyes on your every project, you will usually receive our quotation and get a reply for project within 24 hours.

What is Your Next Step?

This will guide you through our very simple quote submission process. We are excited for the chance to earn your business!