Quality Inspection

Here at APT Mold, our goal is to come as close as possible to the golden standard of 100% perfect parts each and every time. We take great pride in our work, and our entire team is dedicated toward striving for perfection.

APT- Mold Guarantee

Our strict quality standards and inspection process are implemented to make sure we provide the good parts to meet your requirement and find the problem before you catch, allowing us to correct the issue immediately.

Specializations:

Committed staff of experienced quality professionals

Drawing Review

Granite Flatness tables, testing straightness, flatness, & parallelism

Certified metal material testing

Certified plastic raw material testing

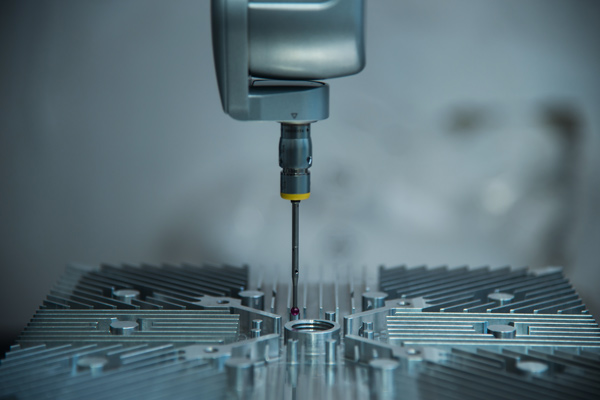

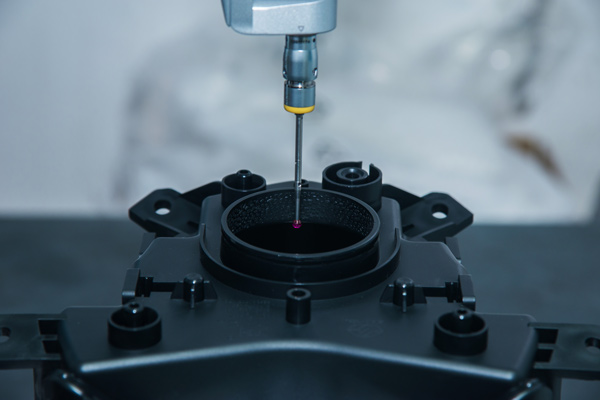

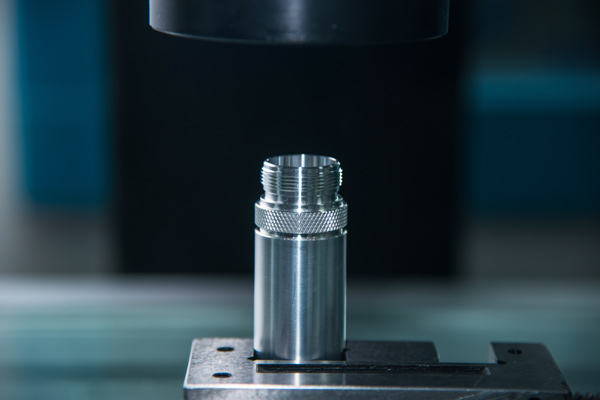

Dimension checking by 2d projector, CMM

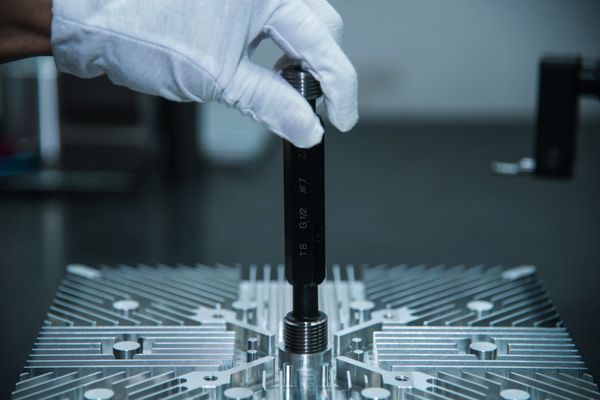

Feature checking by gauge

Color deviation testing

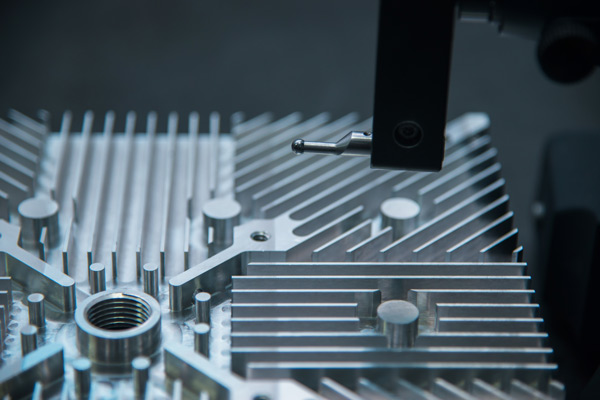

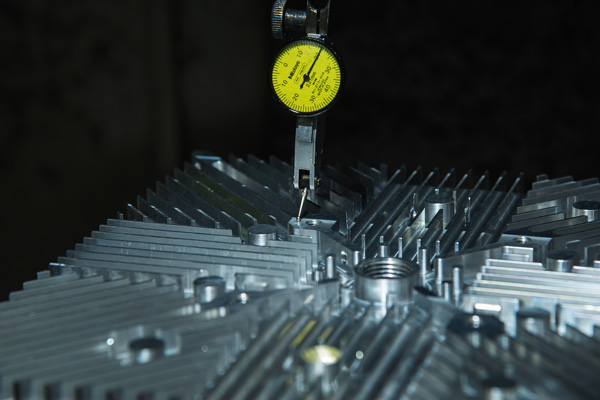

High Gauge Inspection

Meter Calibration

CMM Inspection for Metal Parts

CMM Inspection for Plastic Parts

Projector Measurement

Thread Gauge Inspection

How does APT Mold assure repeatable quality for the parts I receive from you?

Every project, every part, is subjected to our comprehensive quality manufacturing standards. APT utilizes the following quality assurance systems to assure we meet the highest of quality standards: Master Quality Control Plan Documented Inspection Standards Parts can receive Compliance of Certification Materials can receive Compliance of Analysis Material Data Sheets supplied if requested First article inspection reports if requested Receiving inspection data Final inspection data Corrective action Preventive action

What tolerances can I expect from the parts I receive from APT Mold?

Our general tolerances are in line with industry standards. We use ISO DIN 2768 (f) for precision-machined metal parts and ISO DIN 2768 (m) for machined plastic parts. We use DIN 16901 tolerance standards for plastic injection molded parts, unless 2D drawings with specific tolerances are supplied. If certain dimensions are more critical than others, those dimensions plus any manufacturing and technical specifications need to be clearly specified in the 2D drawings. Please refer to DIN 2768 and DIN 16901 standards.

How do you control cosmetic finishes?

Our goal is to manufacture every part in perfect cosmetic condition. For injection-molded parts, that means eliminating all black specks, scratch marks, injection marks, weld lines and dent marks. In the case of painted or powder-coated parts, we provide parts free of runs, orange-peel, overspray, embedded foreign particles, etc. To assure this, we have instituted internal cosmetic inspection standards which you are welcome to review here.

Do you have any color inspection standards?

Yes, we utilize industry-common color standards such as Pantone and RAL. For injection molded plastic parts, 100% color consistency is a challenge, especially with metallic colors, so we have instituted internal cosmetic inspection standards. Generally, colors can be checked by human visual inspection, though we also implement a Color Spectrophotometer whenever needed. Spectrophotometer-recorded Delta E color deviation of less than 1 is considered excellent, while Delta E color deviation of less than 2 is considered acceptable. We also perform these same inspection steps for painted, powder-coated, plated, dipped, and anodized parts.

How does APT Mold assure repeatable quality for the parts I receive from you?

Every project, every part, is subjected to our comprehensive quality manufacturing standards. APT utilizes the following quality assurance systems to assure we meet the highest of quality standards: Master Quality Control Plan Documented Inspection Standards Parts can receive Compliance of Certification Materials can receive Compliance of Analysis Material Data Sheets supplied if requested First article inspection reports if requested Receiving inspection data Final inspection data Corrective action Preventive action

Pantone color chip

RAL color chip

Technical Support

Why Support? The support from APT team will help you shorten the lead time. And cost saving in new product development. We will support your project design for manufacturing.

Innovative Ideas

We have innovative ideas based on design and manufacturing experience will help you trouble shooting and turn your idea into reality and get things done.

Advanced Technology

Our rapid prototyping, Technology in Computer, Aided Design and Computer, Aided Manufacture also with experienced technician will make the parts in high quality for you.

Fast Response

We keep a close eyes on your every project, You will usually receive our quotation and get a reply for project within 24 hours.

What is Your Next Step?

This will guide you through our very simple quote submission process. We are excited for the chance to earn your business!