Prototypes are very important to the manufacturing process, they form an important basis for development, research, and study process. The prototypes are crucial as it assists in pre-production testing and helps in pointing out potential flaws and defects in the original design.

In the past, creating a prototype model was usually time-consuming and very costly. But this all changed with the introduction of CNC prototyping machining techniques. The rate at which prototypes are created is truly impressive, thanks to rapid prototyping it now takes a few hours to create a working prototype.

Ways in which prototype machines have change production landscape

Partly thanks to the ever-changing trends in technology, quick creation of prototypes can be done in a faster and efficient rate. The CNC prototyping machines can create 3D prototypes within a short period.

The prototyping machines use the latest software which has the capability of running these machines from start to finish. The rapid prototyping machines allow you to create any specifications or project designs based on the requirements and needs of the client.

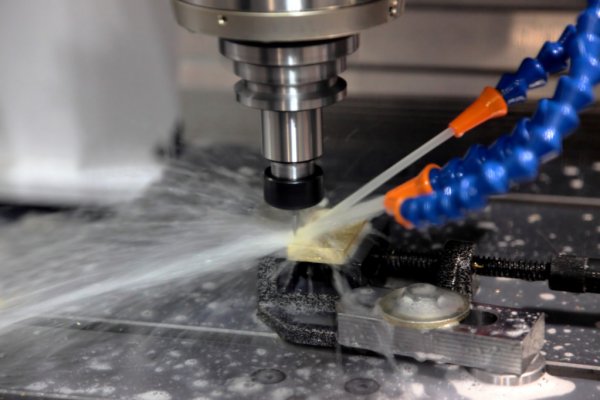

CNC milling machines, *picture from cn.depositphotos.com

The results of CNC rapid prototyping include direct metal laser sintering (DMLS), hybrid tools, injection molding, RTV tools, stereolithography (SLA), selective laser sintering (SLS). Under these mentioned options, you have the freedom to design and shape or part that you want. Exploiting the rapid prototyping process will bring all your ideas and designs to light.

But it’s important worth mentioning that; fast speed can also lead to a loss in other categories. When you produce prototypes or parts within a short space of time, this is due to compensation, the fast speeds will result in a few layers of resin in specific parts of the prototype, this means that the design details will be a bit lower. So, it’s up to you to decide which one do you prefer the most.

The sintering process will churn our parts and products that be used immediately after leaving the prototyping machines. For clients, its not a must your build parts from scratch but rather you can assemble them to form a final product, by doing so the overall prototyping process will be much cheaper and economical.

Stereolithography mainly utilizes UV rays ( lasers) to polymerize all the resins, the lasers will create products adding layer by layer till the final product is formed, prototyping machining is usually an additive process, after the creation of a prototype a wide variety of finishing services can be applied to improve the overall aesthetics and making it more appealing.

Prototyping machining will boost the efficiency of your current project, to be honest, some prototypes look and feel better compared to the final product. As we had mentioned earlier, CNC rapid prototyping used modern and advanced technology that can benefit various fields, it’s not just limited to the manufacturing sector only.

When it comes to prototyping machining, not everybody can operate these machines; they require highly trained and specialized skilled staff, technical experience is key to the success of your prototype making process. With prototyping machining, your dream and reality will be brought to light.