The concept of prototype manufacturing is widely accepted by most of the industries. It remains the essential part of any manufacturing industry as it enables them in perfecting their design, while accelerating the innovation. The Prototype CNC Machining is the process that lets you for a large amount of innovative inputs to go towards the strategy. It also enables you to realize the returns that you achieve with your hard work quickly rather than lately. The Prototype CNC manufacturing actually comprises of 3 vital workflow including 3D modelling, needs assessments and CNC machining or computer numerical control machining. Below you will come across with the facts and details that can help you to understand the CNC machining which is the affordable concept in improvising the operational efficiency and product quality. Moreover, CNC Machining using Prototype technology also reduces the overhead costs and maximizes your overall earnings.

Today, Prototype CNC Machining is widely used in the manufacturing industry and it is progressively eliminating the need of manual handling of the machines like shaping machines, routers, center lathes and vertical millers. Now let us have a look at the benefits that you business can enjoy if you start using CNC Prototype Machines.

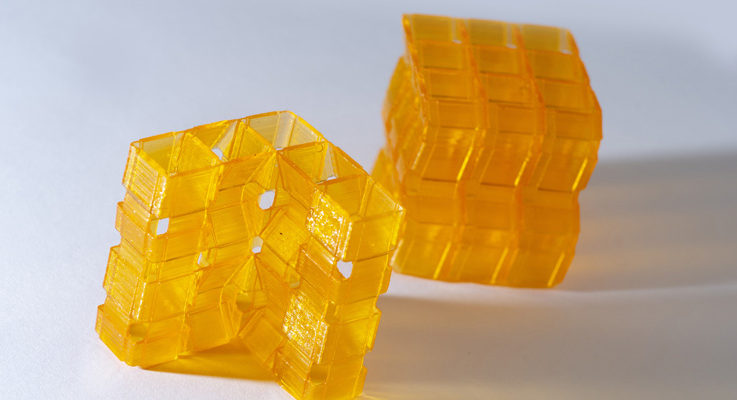

3d printing, *picture from makepartsfast.com

Helping in Automation

The primary benefit of integrating Prototype CNC Machining in your manufacturing business is that it eases automation. This is possible because it eliminates the need of manual labour or machinist from most of the manufacturing phases. You will no longer require operators and machinists in most of the parts of manufacturing because the machine can handle all those operations automatically. It is even possible for the owners to leave the machine unattended during the manufacturing phase or whenever necessary, thereby allowing you to focus on other operations in your manufacturing business.

Because of the automation process of the CNC machine the reliance on the operators would be reduced significantly. This helps you to cut the overhead costs and you will only need handful of workforce in your industry to look after the manufacturing processes and handle the operations. This helps your company to save lots of money that you use for hiring the workforce. The Prototype CNC Machining not only eliminates the need of manual labour, but also boosts the safety because the possible hold-up or the conceivable perilous machining failure will only damage the tools not anyone due to the absence of the machine operator. This way safety at workplace would be enhanced significantly.

The prime benefit of automation is that the Prototype CNC Machining works rapidly and delivery is very faster as compared to the manual operators. These machines are designed to work faster and without any breaks it can work continuously. You can even run the machine at night lately when all employees are gone and you need emergency delivery of products. Being the business owner you will never get agonized about the machinery getting sleepy or demanding for extra allowance for doing extra jobs. This is like a win-win situation for the business owners.

Higher Consistency of Prototype CNC Machining

The Prototype CNC Machining is known to deliver precise outcome every time without faults and errors. This is not possible when you employ manual labour. Even the experienced and most expert machine operator can make minor differences in the finished products. But with the CNC Machining you can ensure to get only precise finished products every time without any errors or faults. This is something that is very essential in today’s competitive world of exchangeable and normalized parts where one error can render the entire machine useless.

So, you can make use of Prototype CNC Machining to deliver a program for your required device. The machine never complains and works for you as much as possible and producing precise replica up to millions every year with highest consistency and precision.

Higher Flexibility

Humans are actually more adaptable and trainable as compared to the machines. But with the Prototype CNC Machining it is possible to re-program the machine in matter of hours to design a new output quickly. This type of flexibility is only seen in the CNC Machining and this is like an edge over all other devices because it requires no conservative revamp for all its essential parts. Because of its higher flexibility and adaptability, these machines keep up to the speed with the ever changing and higher customer demands because it has the ability to change promptly from the making parts in excessive quantity to designing the parts in very short span of time.

So, considering all these facts using Prototype CNC Machining in your business is a feasible business move which any industry can adopt. Today in this highly competitive world, this machine can help businesses to develop creative products affordable and quickly with highest precision and deliver it on time.