CNC machinery

CNC machining is one of the most complex machinery available. It is a manufacturing process in which you have computer software dictating the movement of the machines and the tools. It is an entirely pre-programmed software available. It has been able to coordinate a wide range of complex machinery. It is in use in mills and other places. CNC takes a lot of information to control and monitor how the machines move. It saves a lot of manual labor as well as gives a good hand over precision. You could completely automate the system from one place. Movement in CNC machining usually moves from the X-axis to Y-axis.

History and uses

One of the earliest CNC machines dates back to the 1940s, when motors were made and employed to control the tools of the machine. Since then, technology and machinery have brought out the work to be so much easier. Now a lot of the machinery is entirely electronic. Some of the CNC machines used widely are:

- Plasma cutters

- Lathes

- Electric Discharge machines

- CNC mills

- Water Jet cutters

One of the advantages of the CNC machine is a lot of precision. It involves a lot of small intricate things. It cannot be done with precision by humans. If humans replaced the machine, it would cost the companies a lot of money. They would be responsible for any damage and must be ready to compensate for any losses. All the machines require is the correct code for all the functions to be carried out correctly.

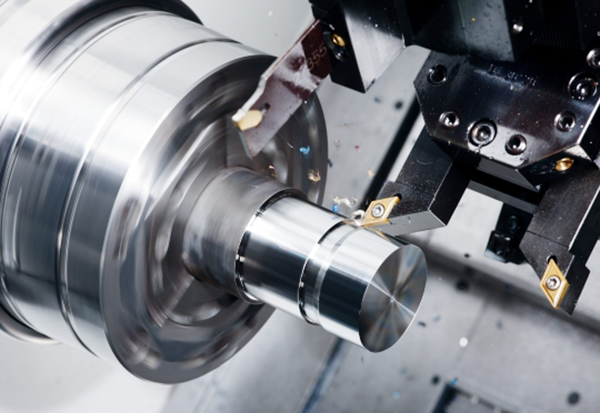

cnc machining process, *picture from cnclathing.com

Process

One of the most important things about a cnc machining china is that it is entirely cost-effective. The life of the machine is way more, and maintenance is way cheaper than manual labor. The machinery usually has some small things to do, which requires a lot of power to do work. Additive processes and assembling layers of material take a lot of work. It is work which is suitable for a machine. Some of the basic steps to the machining process of CNC is:

- Designing the CAD model

- Conversion of the file into a CNC program

- Preparation of the CNC machine

- Execution

The processes are simple. But a small mistake in the model could cost a lot of money and material. It is best to produce a prototype and then produce it in bulk. The errors are set into correction after the prototype has undergone tests.

With the world heading towards technology, several industries have the cnc machining china in place. Some of them are automobile frames, surgical equipment, and gears. These are small intricate places where small tools are in use. Even a minute distance in construction makes a huge difference in the end product. All it requires is precision. There a lot of CNC machines available now. There are few with a different number of axis. You must keep updating the software to keep the machine up to date. The machinery taking over can cause a lot of unemployment, but it could give a better end product.