There is a wide range of tools and factory types of machinery required to perform various tasks in industries at a faster rate. Today, with the contribution of technology, one can easily perform automated tasks. There are many CNC software to help people in performing complex tasks through machines. Some cnc machining china makes use of numerical control tactics. With the reviews and reports, it can be concluded that this machining process has offered high capabilities and better operations throughout the large process. This article consists of all things one needs to know about CNC machining.

Why use CNC machining?

When it comes to CNC machining, every person in the industry is aware of its importance. It is an appliance that is majorly used for manufacturing purposes. The cnc machining china uses pre-programmed dedicated software with the help of tools and machinery. With the help of CNC machining, there is no need to study complex procedures of machinery. The best benefit of this procedure is served in 3-d cutting.

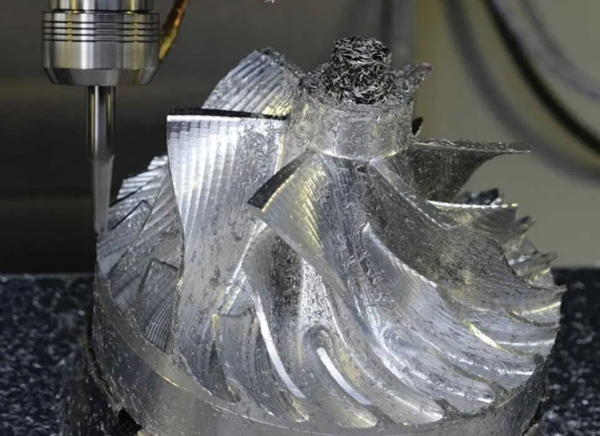

5 axis machining, *picture fromcnclathing.com

How do CNC machines work?

Thanks to CNC machines, many tasks have become in handy to perform. With the help of suitable video demos that explain the usage of all these machines in industries. Some other important tools used in industries can include-

- Wood routers

- Current punchers

- Glass cutters

- 3d printers

- Laser cutters

- Foam cutters

With the help of technology, it is become simple to perform dedicated cutting done by the CNC software. They are pretty robotic and make use of a code generator with an embedded numerical system. These numerical programs are implemented in CNC machines with the help of punch cards. The cnc machining china also consists of looping systems that support closed as well as open-loop machines.

How to set up CNC machines?

There are numerous CNC machines available in the market that can be operated using CNC software. Some of these common machines are mills, lathes, plasma cutters, electric discharge machines, jet cutters, etc. Setting CNC machines is not a difficult task. It should be noted that the CNC program should be running before you start operating with CNC machines. These machines, when used for large-scale operations, can cost a bit higher. There are, however, alternatives to CNC machines as well. The repetitive cycle does take into concern the position and speed of the machine. The main software used for CNC machining is CAD, CAM, CAE.

In the market, there are different kinds of CNC machines available. People can buy the one that satisfies their needs. It is easy to buy cnc machining china based on the one that will satisfy their needs. Based on the type of machine bought, they are priced differently. It is easier to buy these machines online. Many websites offer opportunities to the customers to grab the best discount opportunities along with other services. One should have enough knowledge related to the operations of CNC machining. Last but not least, in industry, CNC machining has come out to serve as the most optimal solution for performing complex manufacturing tasks.