Any manufacturing unit considers the best effective and less time-consuming method for the production of their products in an assembly line. Keeping this situation in mind, many firms have emerged in the level playing field catering to the needs of prototype mold services that not only help to manufacture high volume batches but also create samples for testing and research process.

However, it sometimes becomes difficult to find the perfect firm that suffices what you need. Due to specialization, there are many firms that are related to creating prototype molds but each of their products is different from other firms in some way or the other. As a matter of fact, this should be the case otherwise; they will not be able to sustain the competition in the market. So, you need a prototype mold for your purpose but how you select which prototype mold service would be beneficial for your production entirely depends on some of the considerations. These considerations are not exhaustive in nature but become a crucial part while making the purchase.

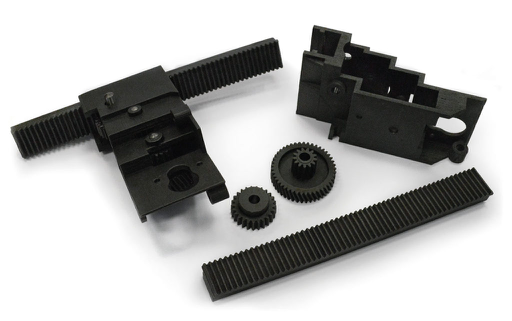

prototype mold, *picture from novatech.net

Considerations of transaction

Any manufacturing or production units have to undertake many measures to cope up with the increasing demand and short supply curve. Apart from this, there is a budget constraint that drives the economic feasibility of installing any machine in the shop floor. In addition to these, every prototype mold service has different molds with different features. So, it is very much required for the decision maker to see if the installation is quite worth it. So, we have listed some of the considerations that one should make before purchasing any prototype mold.

- The requirement of the molds – it is a burning question that every businessman or the production head must ask themselves every day. It is so because the world is changing very fast and if your product can’t make its presence known in the market; your business might sweep off. So, the preliminary consideration that has to be made is whether or not the business needs a prototype mold

- Quantity versus quality achievement – if you find that the product you manufacture has prototype mold application in it, then you have to look at the two aspects. These are qualitative and quantitative aspects. Prototype generally means a miniature working model of the product that is susceptible to various tests to understand the behavior in real life situations. The requirement of quantity will be high if you are approaching several consumers at a time to fill out a survey. In this case, the prototype mold services can accelerate your production.

- Demand and durability – one of the important features of a mold that any business should look forward to are whether the mold is able to meet the demand for the product and if the mold is durable. The costs of the mold are not usually high but the life cycle may be short. So, it is for you to decide whether you want a long term highly productive mold for the purpose or a sophisticated mold just to prepare a test product for research purpose.

- Types of molds – the types of molds also play a crucial factor in determining the production. Depending on the capabilities and design, each of the molds is able to process different numbers of molds with materials of different nature. Some of the most common examples are plastic injection molding, liquid rubber silicone molding, and insert molding.

- Nature of the material – the market has numerous molding services and each of them provides a discreet mold. You can find molds made up of aluminum or molds made of ceramic. The major consideration that you have to make here is to find out the operating temperature that you require and the costs associated with the transaction.

Hence, these are some of the considerations that you need to take care of before entering into the transaction. If you are determined that you require a prototype mold service to install the molds in your shop floor, then you need to find the perfect service amidst the noise.

Things to look for in a prototype molding service

Before we dive into the features we would like you to know that you can outsource the prototype mold to different firms as well as they are specialized and have experts who can do the job for you.

The first and foremost important feature required in the firm is if they have the facility of in-house production. The firm must be able to maintain consistent quality with reduced lead times along with in-house tooling and part production.

Another important aspect that you should be looking forward to is the dynamic market conditions. We all know that the market can be volatile at times and thus, the firm should be able to react swiftly with the changing dynamics.

Lastly, there should be a provision for mass customization of the product as it becomes very necessary to change the features of products to impart a new look and design. The flexibility will also help in eliminating the minimum order concept and leaves you leverage over your competitors.