Do you know what plastic injection molding is? If not then here we will tell you all about its use and advantages and so on! Plastic injection molding is the highly versatile method of making parts as well as products. It is the most preferred method for producing parts as it has several advantages over various other methods of plastic molding. Plastic injection molding is simple as well as more reliable and also highly efficient. You must not have doubts about using this process to manufacture parts.

Here we have given some advantages of using this injection molding:

Detailed features as well as complex geometry

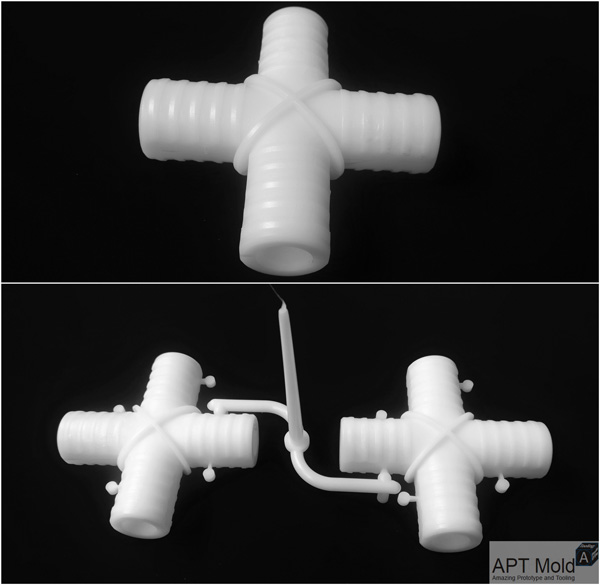

This injection mold is put to excessively high pressure. Thus, plastic inside the molds is pressed harder to this mold as compared to another process of molding. Also because of this extremely high pressure, it is likely to add the huge amount of details in the design of a part. Moreover, because of the high pressure while molding procedure, complex as well as intricate shapes are simply designed and produced which is or else have been expensive as well as complicated to manufacture.

High efficiency

When the injection mold is designed as per customer’s specification as well as press preprogrammed then actual molding process is very fast in contrast to the different process of molding. Plastic injection molding method takes less time and enables more parts to be produced from one mold. Thus, high production output makes plastic injection molds more cost effective as well as efficient.

Enhanced strength

It is likely to make use of the fillers while using the plastic injection molds. Filler decreases the density of plastic when it is molded as well as also it helps in adding more strength to part after it has been molded. In areas where there are parts required to be strong as well as durable the plastic injection are far better to use than the other processes of molding.

Automation to keep manufacturing costs

An automation process is the plastic injection molding. A number of injections molding process are executed by machines as well as robotics which a solitary operator can control as well as manage. Automation helps to decrease costs of manufacturing as overheads are considerably reduced. Moreover, with reduces labor, the overall expense of the manufacturing part is decreased and cost saving can be handover to the customer.

Automation also is responsible for making accurate injection molds. CAD or computer-aided design, as well as CAM or computer-aided manufacturing, allow closing tolerance while making of mold.

Therefore, we can say that using a plastic injection molding is the eco-friendly process. Scarp plastic created during the process is reused as well as reground. Thus, the waste generated while this process is less. So this was all about the plastic injection molding it uses and advantages. You can learn more about it if you wish. You can also make use of this process of injection molding in your industry for more saving as well as a fast operation to produce parts.