Rapid prototyping is the production of the physical products from the CAD models by using different techniques. Rapid prototyping is useful at different phases of the manufactured article. Rapid prototyping can be done various times to get the desired designs of the parts.

You must have heard about rapid tooling but rapid prototyping may bea new term comparatively. It involves the visual creation of the products and then manufacturing them from visualization.

In the context of engineering product pattern, the prototype is an introductory version of the final products. It is used to check the validity the technology, analyze the design and its operating principle then provide product specifications of the final product.

The prototype is an important part of engineering product pattern.

Rapid Prototyping and 3D Printing:

Many people think that rapid prototyping and 3D printing are the same things but this is a totally wrong conception. Additive manufacturing and 3D printing are the manufacturing processes but prototyping is not the process, it is the final product.

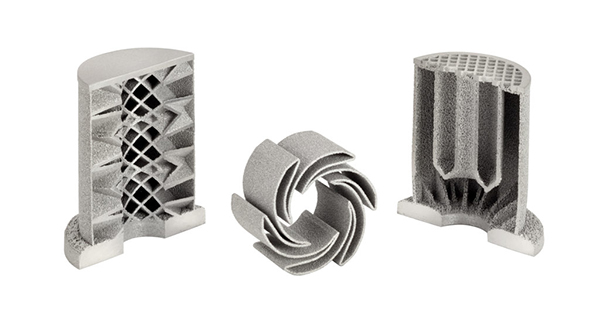

sintered metal 3D printing, *picture from mottcorp.com

Importance of Rapid Prototyping:

Bigger companies should introduce and develop new products rapidly to remain in the race. Quick product production is of utmost importance for the companies in this modern era, where the competition is becoming tougher as time is passing. It is also important for the successful future of the company.

Rapid prototyping is among the main streams of product developments. It is very useful as it helps to achieve the following aims.

- It helps to produce new products faster because it helps to evaluate the product in the initial stages. So little or no changes are required in the final product. Eventually, it speeds up the process by initial evaluation.

- It allows to investigate the functionality and aims of different new idea and to finalize the required or new features of the product.

- Rapid prototyping tells us about the validation of the ideas in early designs and prevents wasting time on non-functional ideas.

Applications of Rapid Prototyping

Some common rapid prototyping applications include

- Well-designed prototypes

- Prototypes of different tools

- Manufacture molds of prototypes

- Visual prototypes

Pros and Cons of Rapid Prototyping:

Like any other method rapid prototyping also has pros and cons. Before choosing any method for your company, it is necessary to read about the working and the positive and negative aspects of the process.

Pros of Rapid Prototyping:

- Reduce the development time of product.

- It is cost-effective as it also reduces the overall cost of product production.

- It eliminates the risk of flaws in the end product by providing an ease to check the features and functionality of the ideas.

- It also enables to evaluate the ergonomics and other factors.

- Increase and improve user participation during the product development stages.

Cons of Rapid Prototyping:

- The accuracy of the product is affected by rapid prototyping.

- Few rapid prototyping techniques are still expensive.

- It has reduced properties of the materials including strength and surface finish.