To understand, rapid tooling is nothing but the process of creation of mold in less time. This technology has started in 1990s. This concept came into picture since engineers started thinking about the reduction of time to build a mold. They wanted to do it within an hour time. At that time mold creation was taking months or weeks.

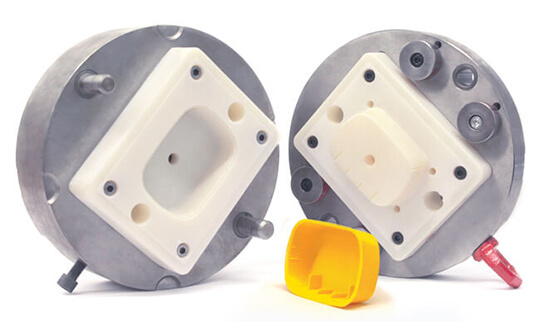

rapid tooling, *picture from poeppelmann.com

A mold which is rapid tooled is best for prototyping parts and especially for molding large number of parts even before the full scale, huge volume actually starts. The part of a tool which is built through process of rapid prototyping is the insert along with cavity and core, and the side actions. Based on the type of rapid prototyping, it is possible to get huge number of cycles out of a tool.

There are many types of rapid prototyping is available today. Based on the required material, accuracy, technology, consistency and the size each type brings its own benefits. Let’s look into some of the limitation of rapid prototyping which must be kept in mind.

In the rapid prototyping, the mold used must be very strong to handle the process of injection molding. Through pounds per square inch which are being clamped, it is possible to measure the injection molding machines. In case if the material of the mold is not strong enough, there is chance that it may not survive. The mold used must be capable to withstand the injections done of hot plastic material.

The mold used must be smooth enough. This will allow clean ejection of the plastic part. Earlier steel molds were used. These are smoothened and polished to ensure easy ejection. But in case of rapid tooling processes, material could build up layers which may not be smooth. This is the reason there must be extra requirement when it comes to smoothing in case of rapid tooling. Otherwise there will be additional which needs to be done after the creation to smooth the parts.

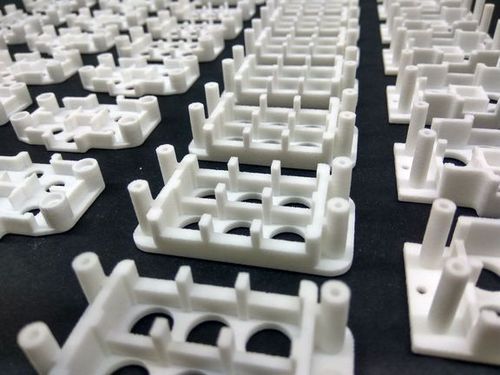

low volume manufacturing, *picture from indiamart.com

Mold should pose great tolerance. In case if the tolerance is less than there may be leakages. This may lead to useless prototypes. So, the tolerance should be between +/- 0.001”. This is not easy to achieve and it depends on the typed of rapid tooling used.

Let’s look into three main types of rapid tooling methods which are available in prototyping.

3D printing:

This can play a major role in number of plastic injection molding. Today there is evolution to the pint that there are addictive manufacturing machines which can print plastic injection mold. There is huge number of benefits of 3D printing. Through this it is possible to create the mold quickly. One thing should be remembered that this is inexpensive in comparison to printing using metal. Through this it is possible to create any geometry required. But there are no exceptional part tolerances in this 3D printing technology. That means it is possible to create any prototype but when it comes to volume this is not the choice.

Laser sintering:

There is a process called sintering. One must understand that only metals are not used in rapid tooling for traditional machines, it is also possible to use plastic injection molds. This is done by fusing metal particles and to make a solvent. This process is called sintering.

This sintering process can be done through spraying powdered metal cloud to laser beam. This allows to draw the mold with desired shape with laser. This process can also be applied to many types of metals along with steel, cobalt, titanium, and chromium. Since the finished product that is mold is made of metal, there is high chance that it withstands heat transfer. So, this is said to be well equipped. Along with heat, it can also withstand pressure and has high ejection capabilities.

One best here is sintering is made unique through allowing the printing in the conformal cooling lines. This helps the cooling of plastic parts very quickly. But meantime one must keep in mind that since the sintering is very fast, it is difficult to achieve the accuracy in terms of required tolerance.

Traditional machining and rapid tooling:

When the rapid tooling processes came to picture, companies which were already using traditional machining start thinking about increasing the speed. So, this made usage of the term rapid prototyping to any tool which built quickly. Even though it is created using the traditional methods, they started calling it rapid tooling. There are companies which can turn the metal mold in few days using traditional machining.

One must understand that just by using rapid tooling it is not possible to save the time which they are expecting. Of course as explained creation process for molds through rapid tooling, can be really fast compared to older methods. But in some cases, this can demand some finishing touches which consumes more time. So, there is chance that post processing may eat up more time. So, there is no guarantee that rapid tooling will be best for all molds. One must do proper selection based on the material and other things before deciding the process.