Regardless of what you intend on producing, one of the most vital steps is to create a prototype that is simple, functional, and efficient, that is the number one priority, so this begs the questions, why is prototyping machining very important.

Well, the answer is quite simple, prototyping is used to clarify patentable features, explaining all the associated cost and issues that has to arise, and testing the overall design of your prototype.

So, in this article, we are going to dig a little deeper and show you some of the benefits you should expect from prototyping machining.

Testing and evaluating your design

Drawing your designs and ideas is very simple, but when it comes to its application bringing it to light; then it becomes another issue. When it comes to the creation of a prototype, you will have a similar version of the end-product allowing you to assess and gauge the product and decide which parts need modification or revision ensuring you get a perfect and excellent part or product that will sell on the market.

During the evaluation phase, you will pinpoint issues that would have been otherwise impossible to point out. The creation of a prototype through prototyping machining will give engineers time to test and experiment on the product before the commencement of full production.

Let’s paint a picture for you, just imagine ordering thousands of products only to find out some of the design and features have flaws. If big corporations make these mistakes, then small firms should never ignore the importance of prototyping.

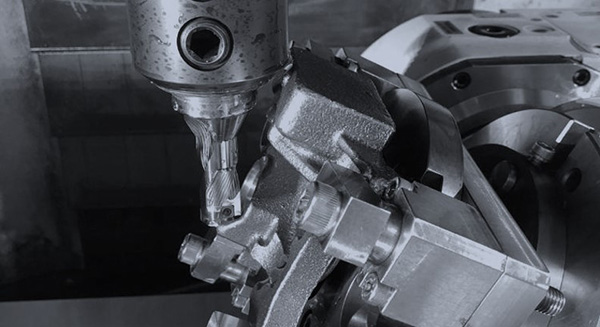

5 axis CNC machines tool crash, *picture from hwacheonasia.com

Explanation of production cost and issues

Once full production begins, it can be time-consuming and costly to make changes or alter the original design. When you create a prototype before mass-production, it will give you an idea of the looks and aesthetics of the product allowing you to decide on whether any steps can be removed, joined, or altered.

By following these steps, not only will you keep the production cost within the set budget but also you will be able to streamline the entire production process. In any case, you may encounter some difficulties or the entire production process has some bit of problem, then it’s better to know all these during the prototyping phase rather than later on.

Knowing things before-hand will enable your design team to choose the best course of the production.

Providing evidence for part and products to be sold

When you have a working and functional model, you can be able to demonstrate and show it to potential customers and investors. It’s the ultimate marketing presentation, without a prototype; it will be extremely difficult to get orders.

But if you have a prototype on hand. It will be significantly easy to showcase your concept hence it will be simple to get purchase orders.

However, factoring in the client’s specifications and needs is very important. There is no need to create a working prototype that won’t be liked by potential clients. If they won’t love it, definitely they will not buy it. Its vital to carry out external testing and focus groups of the prototypes should be addressed before final production can begin.