CNC machining is one of the foremost utilized fabricating forms for models and low volume generation runs. It offers incredible preferences in terms of speed and run of materials accessible and is additionally decently fetched compelling when compared to other forms. CNC is profoundly flexible and particularly with 3, 4 and 5 hub machines, the sort of portion and geometries able to be machined are shifted. That said it too pays to be mindful of certain plan components which may diminish the prototype machining time, complexity, and fetched of your work. First and most basically the sort of fabric includes an enormous effect upon fetched. CNC machines can cut everything from plastics to metals but there are a few materials that are simpler to work with than others. If we make plastics, to begin with, all there are several common and simple to machine grades of plastic.

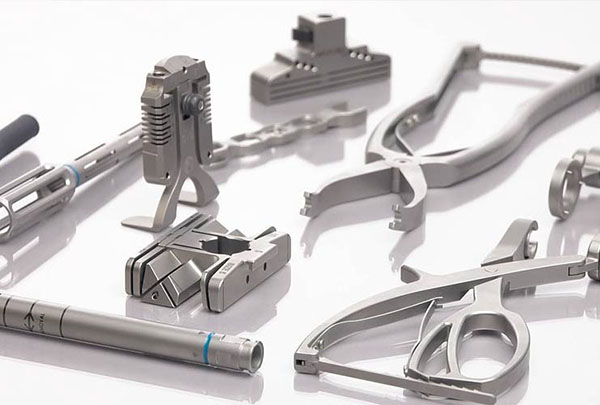

Precision medical parts, *picture from rapiddirect.com

On the other hand, PP or POM is more troublesome to cut and inclined to distort, which suggests the fabricating handle is very a bit more complicated expanding the costs. Metal materials moreover offer different ranges of machinability, aluminum could be a decently soft metal and so simple to cut and speedy to the machine. Steel may be a much harder fabric and so much harder on the machines, typically regularly reflected within the costs of the parts. Another thing to consider is the portion geometry, here and there are so numerous distinctive views may be impossible to list them all.

However, there may be a speedy rundown of many concepts when talking about prototype machining. CNC machine cutter instruments are circular, so indeed the littlest breadth cutter is getting to take off a sweep within the corner. If you wish square corners this will require post prepare wrapping up either by hand on plastic parts or spark erosion on metals. On the off chance that you’ll be able to get absent with rapid, and the greater the way better, you’ll bring the costs of prototype machining down a small.

Prototype Machining Concept and Parts Manufacturing:

For a few parts, it may moreover make sense to part them into a few isolated parts in case they are to be machined. Where prototype machining in one piece might have focal points in terms of quality and restorative benefits regularly on the off chance that you’ll be able to accept the portion being part you’ll be able to spare a few cash. Compare regions 1 and 2 within the picture underneath. On this occasion, it may make sense to part the portion as region 2 makes the portion more troublesome to the machine, increments the introductory fabric costs, and would require an extra machine setup.

Prototype Machining and Complex Parts:

Profound pockets, these are moreover precarious to the machine and regularly result in apparatus chatter clearing out you with flawed surface wraps up. On the off chance that you’ll do absent with these sorts of features all the way better, on the off chance that not the most excellent proportion between lengths to profundity is 4:1.

Prototype Machining and Parts Resistances:

Other issues that drive up costs are the resistances required on the parts, clearly the higher the required resiliences the more care and consideration required when machining the portion.

Events of Prototype Machining Concept:

Lean walled highlights are moreover precarious to the machine and simple. It ends up harming so many professionals for most of their manufacturing tasks.