CNC machining is one of the preeminent utilized creating shapes for models and low volume era runs. It offers mind-blowing inclinations in terms of speed and run of materials open and to boot conventionally brought compelling when compared to other shapes. CNC is significantly adaptable and especially with 3, 4, and 5 center machines, the sort of parcel and geometries able to be machined are moved. That said it as well pays to be careful of certain arrange components which may decrease the prototype machining time, complexity, and get off your work. To begin with and most essentially the sort of texture incorporates a gigantic impact upon gotten. CNC machines can cut everything from plastics to metals but there are a couple of materials that are less difficult to work with than others. In the event that we make plastics, to start with, all there are a few common and straightforward machine grades of plastic.

Parts Production And Prototype Machining:

For some parts, it may moreover make sense to portion them into a number of disconnected parts in case they are to be machined. Where prototype machining in one piece might have central focuses in terms of quality and helpful benefits frequently on the off chance that you’ll be able to acknowledge the parcel being portion you’ll be able to save some cash. In this event, it may make sense to portion the parcel as locale X makes the parcel more troublesome to the machine, increases the early on texture costs, and would require an additional machine setup.

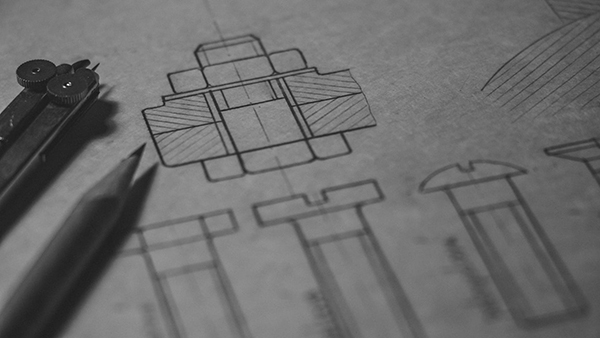

Design for cnc machining, *picture from marshallmfg.com

Parts Resistance And Prototype Machining:

Other issues that drive up costs are the resistances required on the parts, clearly the higher the specified resilience the more care and thought required when machining the parcel. On the other hand, PP or POM is more troublesome to cut and slanted to misshape, which recommends the creating handle is exceptionally a bit more complicated growing the costs. Metal materials in addition offer different ranges of machinability, aluminum may well be a modestly delicate metal and so straightforward to cut and rapid to the machine. Steel may be a much harder texture and so much harder on the machines, regularly frequently reflected inside the costs of the parts. Another thing to consider is the parcel geometry, here and there are so various unmistakable sees may be outlandish to list them all.

Difficult Parts And Prototype Machining:

Significant pockets, these are in addition unstable to the machine and frequently result in device chatter clearing out you with imperfect surface wraps up. On the off chance that you’ll do missing with these sorts of highlights all the better, on the off chance that not the foremost amazing extent between lengths to significance is 4:1.

Prototype Machining Operations And Events:

Incline walled highlights are besides tricky to the machine and straightforward. It closes up hurting so numerous experts for most of their fabricating assignments. Be that as it may, there may be a fast rundown of numerous concepts when talking approximately prototype machining. CNC machine cutter disobedient are circular, so without a doubt, the tiniest breadth cutter is getting to require off a clear within the corner. On the off chance that you want square corners, this will require post plan wrapping up either by hand on plastic parts or start disintegration on metals. On the off chance that you’ll be able to induce missing with quick, and the more noteworthy the better, you’ll bring the costs of model machining down a little.