At some point, the economic power play in the world shifted, and many companies realized that shipping their manufactured products was suddenly much cheaper than actually assembling them in their own plants across the globe. That little label that reads “Made in China” in almost every product you own has become a universal sign on how centralized is the manufacturing process is in this particular country. We are not here to analyze the implications of such a trend to the world economies. We are here to explain how this can help you to improve your profile as a new player in the business field.

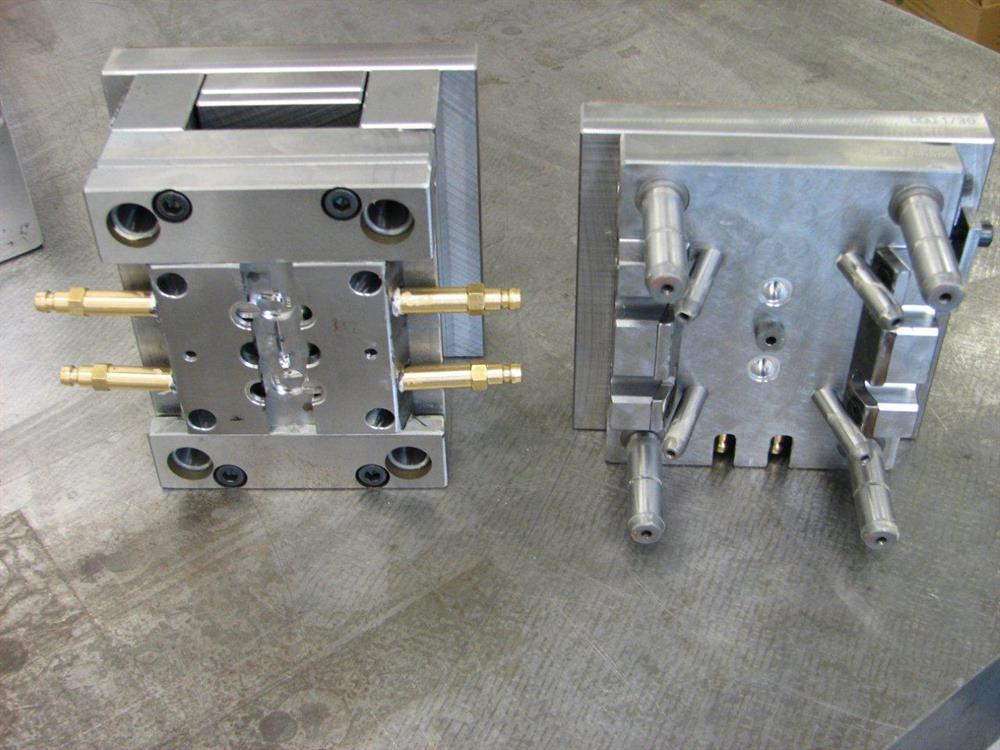

rapid tooling, *picture from protocom3dp.com

The Secret Behind China Economic Outburst

Whatever you realize it or not rapid tooling China is an actual thing and it has overtaken the creation of products in a way that you wouldn’t believe. Giants such as Tamaashi-Bandai and Apple have their devices and products assembled in the mainland. The only reason for this is because is cost-efficient and provides the same kind of output you can expect from handcrafted work at record speeds and increased quality features. Just think about it for a moment: if you had a room of well-intentioned workers without the proper technology to handle your product or the option to work with someone who has all the precision tools to deliver precisely what you need who would you choose to work with?

The New Role of Chinese Manufacturers

The way things are handled in rapid tooling China services leave little room for mistakes. Manual assembly lines are almost dead across the world with human handy-work relegated to the role of supervision or to provide exclusive details to products that not even the new tooling technology is able to offer. This claim is no disregard to the quality traits that only the trained human eye can provide, is a statement of facts about realities that are happening each passing day. The most significant feature that most of these services can offer without hesitation is an expanded margin of profits in a short amount of time. Rapid tooling is that effective and can deliver finished products in just a fraction of the time of other manufacturing means.

The Fight for Control

While many companies are at odds in China to get the largest share of the manufacturing market, they still have to deal with the high number of new players looking to get their piece of the pie. Most rapid tooling China services run on the premises of small business by the volume. Even big manufacturers have embraced this model since it’s an already proven fact that entrepreneurship is a trend that will keep on the rise for years to come. Most of these developers are running their companies on the literal dollar and a dream. The low costs of manufacturing using modern technology have made it possible for these guys to get their shot and earn their share. Most manufacturers don’t seem to mind as long as they keep getting business.